Description

Features:

- Can be used in any environmental conditions

- Adapted to various standard installation interfaces on the market (ER probe. weightless coupon)

- Changes in site conditions do not affect the continuity of monitoring;

- Bate monitoring includes real-time pitting corrosion/general corrosion/pitting corrosion:

- The alarm of pitting corrosion can be displayed:

- The lifetime of the ER probe is indicated by the signal.

Description in detail

Resistive probes (ER) use metal sensing elements. The element is destroyed after it is corroded by the medium in the environment in which it is used. Then its geometry changes. According to Ohm’s law, the resistance of a metallic element is related to its geometrical size. Therefore, the resistance change before and after the corrosion of the component can be measured.

The corrosion rate (mm/a) can be calculated by combining the time monitoring of the two monitoring readings. Usually, the resolution of the resistance probe is one-thousandth (1/1000) of the thickness of the probe-sensitive element. Depending on the selection of Resistive probes of specific thickness and sensitivity enables corrosion rate monitoring in different media.

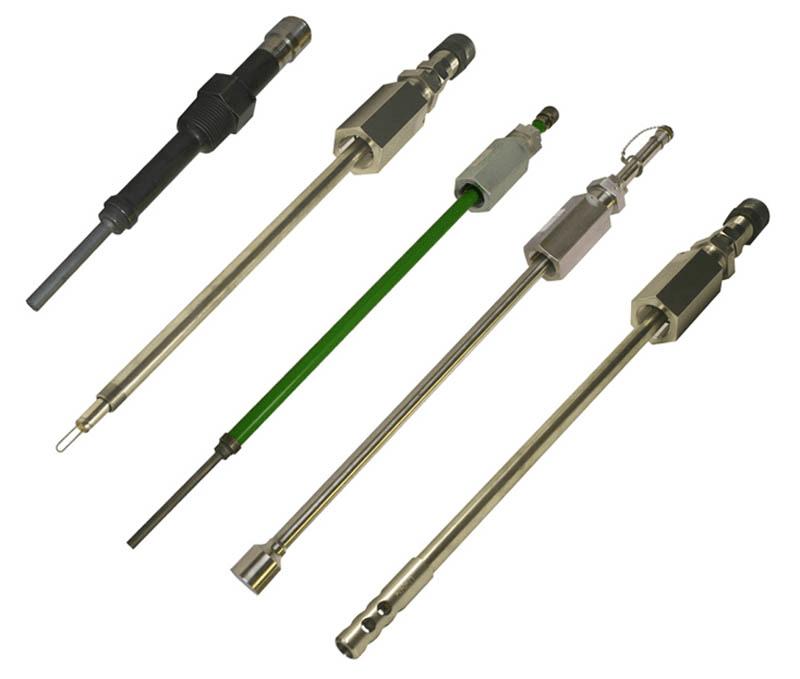

ER Resistive probes metal sensing elements can be made in various geometric sizes, thicknesses, and materials. It includes coils, tube coils, sheet coils, cylinders, spirals, flat heads, sheets, and other shapes.

The resistance probes have a wide range of applications.

Almost all corrosive medium environments can be used. It includes the gas phase, liquid phase, solid phase, and flowing granular media. The signal feedback time of the resistance probe is short and the measurement is rapid. Therefore, it can reflect the corrosion of equipment and pipelines in time. This keeps the internal corrosion of equipment and piping under constant monitoring. Therefore, this method is an indispensable monitoring method for severely corroded parts.

However, due to the limitation of the measurement resolution of the instrument, the measured data are greatly affected by the change in the corrosion rate of the process medium. Therefore, the measurement results may sometimes be biased. For the resistance probe installed for the first time, it takes about 2 weeks to stabilize. Only then can reliable corrosion data be monitored. At the same time, the resistance probe method cannot measure the instantaneous corrosion rate. It is even less capable of monitoring local corrosion rates. The smaller the thickness of the probe, the higher the sensitivity and the shorter the service life.

Generally, it is used in environments with extremely high precision requirements and relatively weak corrosion. When conductive substances (such as sulfide corrosion products) are attached to the surface of the component, the measured corrosion rate will be inaccurate. In terms of drug evaluation, it cannot respond in a short time. Because metal resistance is affected by temperature, the data of ordinary resistance probes fluctuate greatly and are unstable due to temperature.

Especially in areas with a large temperature difference between morning and evening, such as oceans and desert areas, it is more obvious. However, the staff took temperature compensation samples. However, the response of the compensation sample to temperature fluctuations (especially rapid temperature changes) lags behind that of the test sample. This also introduces errors in the measurement.

Metal sensing elements for resistive probes (ER).

The element is destroyed after it is corroded by the medium in the environment in which it is used. Its geometry changes. Using Ohm’s law, the resistance of a metallic component is related to its geometrical size. So we measure the resistance change of the components before and after corrosion. The time monitoring of the two monitoring readings is then combined to calculate the corrosion rate (mm/a). Usually, the resolution of the resistance probe is one-thousandth (1/1000) of the thickness of the probe-sensitive element. They realize corrosion rate monitoring in different media by selecting probes with specific thicknesses and sensitivity.

Reviews

There are no reviews yet.