Description

The corrosion probe is an effective tool to study equipment corrosion. It can continuously monitor the corrosion status of equipment during operation, accurately reflect the corrosion rate and its changes in each stage of equipment operation, and can be applied to various media. It is not affected by the conductivity of the medium, and its use temperature is limited only by the material.

The working principle of the corrosion probe

The corrosion rate measured by the corrosion probe is obtained by the linear relationship between the cross-sectional area and the resistance at any time under the premise that the length of the corrosion probe wire remains unchanged. In order to eliminate the measuring error caused by temperature, a temperature compensation element is added to the measuring structure.

In corrosive media, as a measuring element of the metal wire is corroded, the length of the metal wire is unchanged, the diameter decreases, and the resistance increases, through the change of the resistance to convert the corrosion-thinning amount of the metal wire. When the material of the wire used is the same as that of the equipment being measured, the corrosion rate of the wire can be used as an approximate representation of the corrosion rate of the equipment. Corrosion probe technology is tested based on the above principles.

The corrosion probe is used to measure the corrosion rate of metal by the linear relationship between the cross-sectional area of conductor resistance and resistance at any time under the premise that the length of the corrosion probe wire is unchanged. Accordingly, the cross-sectional area of metal materials with a certain length decreases, and the resistance value increases after corrosion thinning. As long as the resistance change value is known, the thinning amount can be calculated. In order to eliminate the measuring error caused by temperature, a temperature compensation element is added to the measuring structure.

The measuring principle of corrosion probe: In corrosive media, as a measuring element of the metal wire is corroded, the length of the metal wire is unchanged, the diameter decreases, and the resistance increases, through the change of resistance test to convert the corrosion thinning amount of the metal wire, and then represents the corrosion amount of the wall thickness.

In corrosive media, as a measuring element of the metal wire is corroded, the diameter of the wire decreases, the resistance increases, and the resistance change can be measured by the principle of bridge balance to convert the corrosion thinning of the metal wire. When the material of the wire used is the same as that of the equipment being measured, the corrosion rate of the wire can be used to approximately represent the corrosion rate of the equipment.

The establishment of corrosion probe corrosion monitoring is an effective means of corrosion monitoring, which can display the corrosion condition of equipment pipeline in time, discover abnormal corrosion conditions in time, and notify the relevant management departments to take corresponding corrosion control measures to avoid production safety accidents caused by equipment corrosion.

The design of corrosion probe data processing software is simple and practical, which can effectively realize the management of probe data, improve the efficiency of data processing, and facilitate the query of corrosion data.

Corrosion probe applicable temperature

Low temperature -20-120℃ Applicable pressure range ≤20Mpa

High temperature 120-200℃ Applicable pressure range≤2.0Mpa

The corrosion probe is suitable for various corrosive media, both electrolyte and non – electrolyte

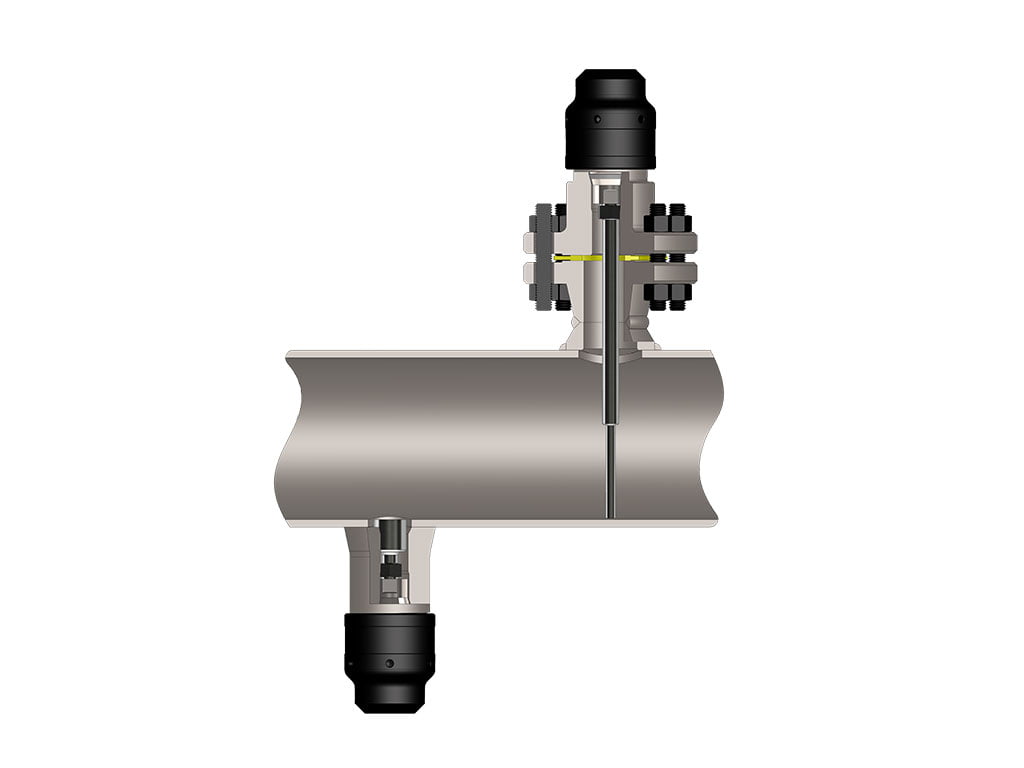

Pressure removable mounting of the probe

In the actual field, the pressure detachable method is often used to install the probe. This installation allows the probe to be removed and replaced without bypass and without downtime. But this way is mostly used in low-temperature equipment and pipelines. Oil-resistant gasket sealing materials are generally selected. The material is an oil-resistant rubber asbestos board, and the sealing surface of the flange is selected as the sealing surface.

No pressure flange installation

The pipe diameter to be detected must be at least 150mm, the length of the probe deep into the pipe must be at least 100mm, and the length of the short connection must be at least 210mm. In order to ensure the stability of the probe, an annular packing ring is often added at the stub outlet to play a fixed role.

Whether it is a detachable installation with pressure or a flange installation without pressure, it is generally recommended to install in bypass, sideline, or other switchable positions at high temperatures, which can reduce the probability of accidents and increase the safety factor. The selection, material, type, and environmental parameters of short connections, flanges, and valves in the installation process should be consistent with the pipeline design standards.

Since corrosion probe sensors are mostly used in the field and need to withstand the effects of rain erosion and external invasion in the natural environment, corrosion probe sensors need to have a certain impact resistance ability. Meanwhile, the tightness of the equipment should also meet the requirements to ensure that the monitoring process is not easy to be interrupted, and the probe monitoring results have high accuracy. When the corrosion probe is used for corrosion monitoring in different environmental types, the reliability of the measurement results must be kept within a certain range.

corrosion probe

Reviews

There are no reviews yet.