Description

The use of corrosion probes

The corrosion rate measured by the resistance probe is obtained by the linear relationship between the cross-sectional area and the resistance at any time under the premise that the length of the resistance probe wire remains unchanged. To eliminate the measuring error caused by temperature, a temperature compensation element is added to the measuring structure.

The effective thickness of the tubular inductance probe is 0.25 mm and 0.5 mm, and the original thickness is 0.5 mm and 0.75 mm, respectively. The effective thickness used in this test is 0.25mm.

Corrosion probes need to be exposed to corrosive environmental conditions, so the following aspects should be considered when using probes in the field

(1) Ensure that the corrosion probe is exposed to the corrosion environment to be monitored;

(2) Strictly abide by the operation under working conditions, and do an excellent job of probe maintenance and replacement.

With the increasing proportion of heavy oil processing in China, the corrosion problem of refinery production equipment is becoming more and more serious and complicated, which leads to the unprecedented severe test of the safe operation of refinery equipment. To control the corrosion of refinery units in real time, corrosion probes are widely used to monitor the operation of refinery equipment. The new inductor probes are favored by refineries because of their advantages of relatively simple operation, easy maintenance, real-time data acquisition, and reliability. The principle of the inductance probe is to apply the high-frequency current signal to the tubular measuring element. When corrosion loss occurs, the resistance value of the tubular component increases and the high-frequency voltage drop also increases. The corrosion rate is obtained by using the electrical signal change at different time periods.

The significance of corrosion monitoring

In recent years, with the shortage of crude oil resources, most petrochemical enterprises process a large number of imported high sulfur and high acid crude oil, the quality of crude oil is increasingly inferior, and the corrosion of equipment is increasingly serious. The corrosion in oil refining units directly causes equipment loss, and even causes corrosion perforation, resulting in shutdown and production or other major fire accidents, which brings amazing economic losses. If corrosion perforation or brittle fracture caused by corrosion is unknown, it may lead to a larger accident or even personal injury.

However, there are many forms of corrosion failure, and the influencing factors are very complex, so the adoption of anti-corrosion measures can not be generalized. Corrosion monitoring and detection technology is one of the important means to effectively guide the anti-corrosion work, Its application has very important significance:

(1) To monitor and evaluate the effect of corrosion prevention measures taken, so as to provide a basis for strengthening corrosion management and scientific decision-making;

(2) Give early warning to potential corrosion hazards to prevent accidents;

(3) Evaluate the service status of the equipment pipeline and predict the service life of the equipment pipeline;

(4) Determine the degree and form of corrosion, analyze the causes of corrosion, and formulate corresponding corrosion control measures.

Corrosion probe monitoring

Corrosion probe corrosion monitoring to measure the change of resistance value of metal components (called a probe) after corrosion in the process medium and calculate the corrosion rate of metal in the process medium. Resistance probe technology is the most widely used online monitoring technology in oil refineries. It can be used in almost all medium environments in oil refineries, including gas, liquid, solid, and flowing particles. The probe measuring element can be made of different materials according to the needs of the field.

The signal feedback time of the corrosion probe monitoring to measure the change of resistance value of metal components (called a probe) after corrosion in the process medium and calculate the corrosion rate of metal in the process medium. Resistance probe technology is the most widely used online monitoring technology in oil refineries. It can be used in almost all medium environments in oil refineries, including gas, liquid, solid, and flowing particles. The probe measuring element can be made of different materials according to the needs of the field. the corrosion probe is short and the measurement is rapid, which can reflect the corrosion condition of the equipment pipeline in time. However, due to the limitation of the measurement sensitivity of the instrument, the measured data is greatly affected by the change in the corrosion speed of the process medium, and the measurement results will sometimes be biased.

Corrosion probe main performance index

Corrosion probe applicable temperature: -20-120℃.

Sensitivity: The sensitivity of the probe can be divided into high, medium, and low, respectively suitable for weak, medium, and strong corrosion environments.

High sensitivity probe (measuring element radius 0.1mm): Sensitivity of 0.1um, corrosion loss can be measured in 4 hours in the corrosion rate of 0.2mm/an environment, the effective life of 3 months.

Low sensitivity probe (measuring element radius 0.5mm): Sensitivity of 0.5um, corrosion loss can be measured in 8 hours in corrosion rate 1.0mm/an environment, the effective life of 6 months.

Maximum transmission distance: 1200m, maximum measurement distance: 30m (distance between the probe and measuring instrument)

The purpose of online corrosion monitoring technology:

(1) Monitor the corrosion behavior of metal in a real environment, monitor the corrosion rate of metal, and take anti-corrosion measures at any time according to the understanding of metal corrosion situation, control the corrosion rate of metal within a reasonable range;

(2) According to the monitoring data, the corrosion rate can be calculated, the remaining wall thickness of the equipment and the corrosion of the equipment internals can be calculated, and the equipment can be repaired regularly to ensure production safety.

The resistance probe method (ER) is the only real-time, online, instrumented measurement technique available for all types of corrosive environments, compared to the corrosion test sheet method. The resistance probe ER is referred to as an “electronic” corrosion test piece. Like the test piece weightlessness method, the resistance probe measures metal loss.

The resistance probe method has the following advantages:

① It can be applied to all working environments: gas phase, liquid phase, solid phase, particle-containing fluid;

(2) The corrosion rate can be obtained directly;

③ During its service life, the probe can always be placed in the pipeline;

④ Rapid response to corrosion change, can be used for alarm.

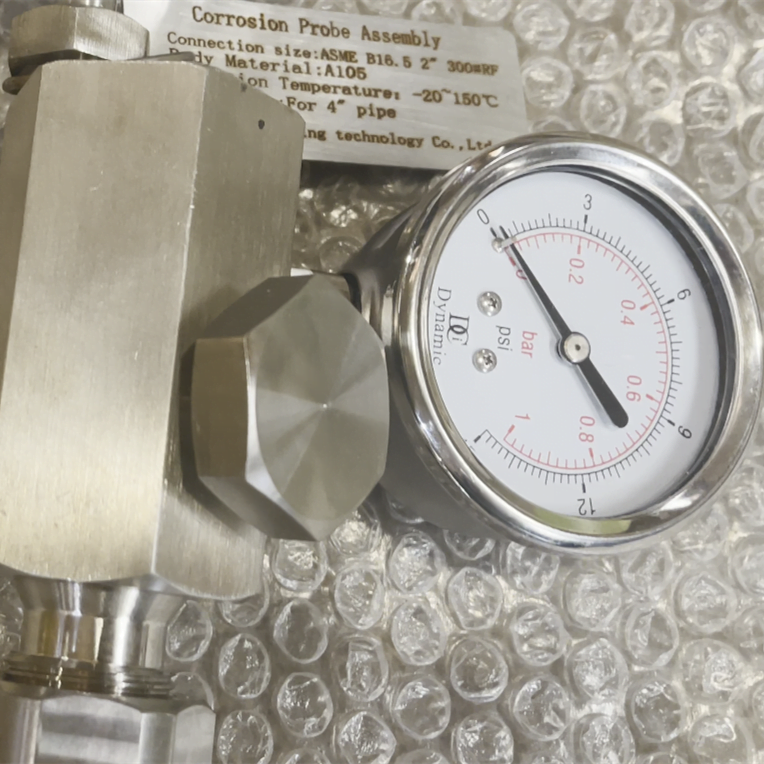

corrosion probe

Reviews

There are no reviews yet.