Description

The gauging disc is usually mounted on a common pig, preferably a bi-directional straight pig. Because the two-way straight plate has better support than the leather bowl.

The installation position is generally in front of the first sealing disc at the end of the two-way straight pig. A gasket should be added between the gauging disc and the sealing disc. If necessary, two washers can be added to increase the space for the gauging disc to bend back.

The operating condition of gauging disc

The running speed of the gauging disc is better between 1-3m/s…

Precautions for gauging disc operation

The installation position should be correct;

Be careful not to damage the measuring plate when the pig with the measuring plate is loaded into the ball cone and removed from the ball cone.

Accurate recording of various operating parameters;

Complete gauging disc operation report in time.

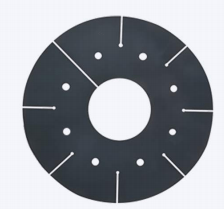

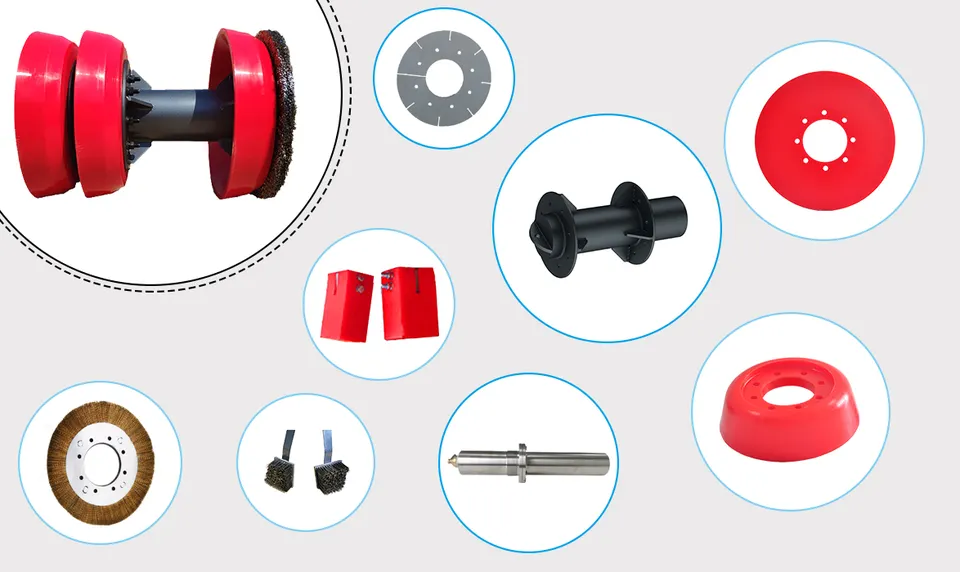

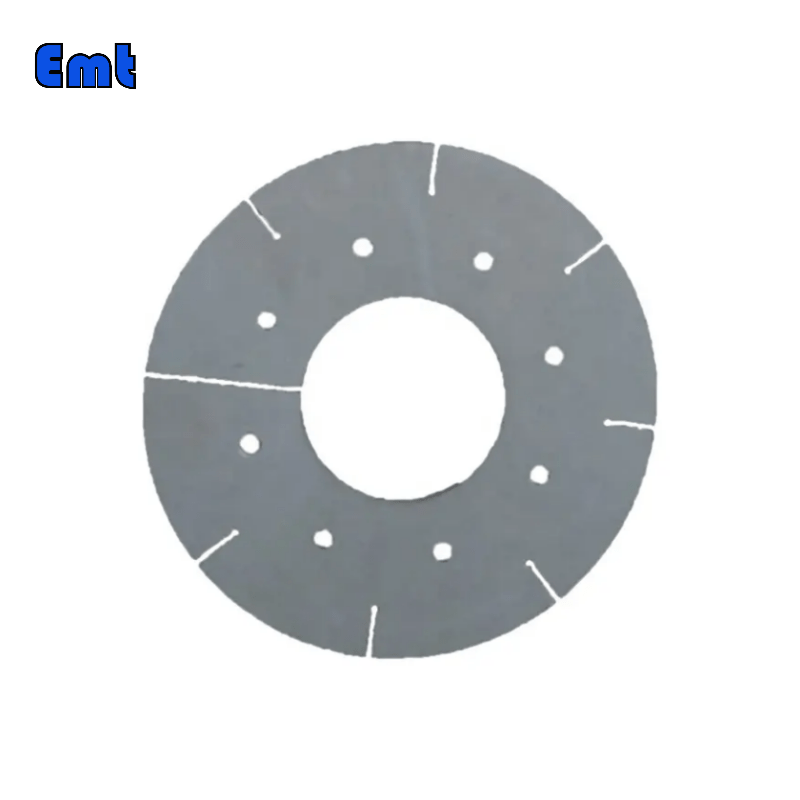

The caliper pig equipped with the aluminum gauging disc is mainly used to check whether deformation occurs along the pipeline. Its main structure includes a support frame, sealing bowl, support plate, gauging disc, signal transmitter, pig head impact buffer components, etc. Its main working principle is: that the caliper pig runs in the pipeline. After the deformation position of the pipeline, the aluminum gauging disc will collide with the pipeline due to the reduction of the pipe diameter, resulting in the deformation of the aluminum gauging disc. After taking out the pig, the deformation of the pipe can be judged by analyzing the deformation and damage of the gauging disc.

When the cleaning pig passes through the U-shaped pipe bend, the possibility of the gauging disc colliding with the outer wall of the elbow is mainly affected by the pig’s movement speed. The larger the motion speed of the pig, the greater the centrifugal force generated when the pig passes through the elbow. When the centrifugal force exceeds the yield limit of the front support plate of the pig, the front support plate will be deformed, and the gauging disc will collide with the outer wall of the elbow. The critical value of centrifugal force can be calculated by the yield limit of the pig front supporting plate, and then the critical motion velocity of the pig without colliding with the outside wall of the elbow can be calculated.

The possibility of collision between the gauging disc and the inner wall of the elbow is mainly affected by the geometric characteristics of the pig and the elbow. When the diameter of the gauging disc is large and the curvature radius of the elbow is small, the gauging disc may collide with the inner wall of the inner arc side of the elbow. The critical relationship between the geometric characteristics of the pig and the elbow can be calculated by taking the critical condition that the measuring plate just touches the inner arc side wall of the elbow.

In the process of caliper pigging, the conclusions obtained from the analysis can be used to guide the modification of pig design and the adjustment of the control scheme in the pigging process, so as to ensure that the caliper pig does not hit the pipeline at the undeformed elbow during its operation in the pipeline.

Pigging, measuring the diameter

Before the subsection pressure test, the pig must be used for subsection pigging, pigging times not less than two times, to the open end no longer exclude debris as qualified.

After the pig is qualified, a pig with an aluminum gauging disc should be used for the pipe deformation caliper. It is advisable to use the caliper pig for the pipe caliper. The diameter of the caliper disc should not be less than 90% of the designed minimum diameter of the pipe in the caliper section. When the measuring plate passes through the pipe section, if there is no obvious deformation, bending, or significant scratches, then the measuring diameter is qualified. Suppose there is obvious deformation of the side plate. In that case, the cause of the deformation of the pipeline and the location of the deformation should be analyzed. The pipeline should be rectified, and then the side diameter should be rebuilt until qualified.

Pipeline sizing

Requirements: The measuring plate shall be made of aluminum, and the diameter of the measuring plate shall be 90% of the inner diameter of the maximum wall thickness steel pipe or elbow (pipe) in the measuring section.

Method: Using a temporary transceiver device, push the caliper with compressed air to move the caliper from the head end to the end at a certain running speed. And fill in the record carefully.

Acceptance criteria: When the measuring plate passes through the pipe section without obvious deformation, bending, or large scratches, it is considered that the measuring diameter is qualified.

Pipe through the ball, pigging, diameter measurement

When passing through the ball pig, the walking speed of the pig in the pipe should be kept uniform, and the walking speed of the pig should be controlled by the exhaust volume of the compressor and the pressure gauge. Generally, the walking speed of the pig should be held at an average of 4-5km/h. The working pressure should be 0.05Mpa-0.2Mpa, such as encountered resistance can improve the working pressure, In the pipeline cleaning in the pig blocked phenomenon, analyze the reason, and improve the pushing pressure, but the maximum pressure should not exceed the rated pressure of the transmitting and receiving cylinder, due to the deformation of the pipeline can not be normal cleaning and diameter measurement, necessary emergency measures should be taken to repair the pipeline.

gauging disc

Reviews

There are no reviews yet.