Description

The definition of bidirectional pipeline pig

Why use a bidirectional pipeline pig?

Pipelines in industrial production and civil sectors have a wide range of applications, For water, oil, gas, and other fluids pipeline transport has a variety of advantages such as convenience, fast, and low cost, especially in the long-distance transportation process can show its advantages. However, dirt will be deposited or formed on the inner wall of the pipe during long-term use. Such as in the water pipeline will form a scale or dirt scale, the inner wall of the oil pipeline will form an oil scale or wax, in the industrial gas pipeline will also form coke carbon and other dirt. These dirt deposits in the pipeline greatly increase the resistance of the fluid in the conveying process, which not only reduces the transmission efficiency but also dramatically increases the power consumption required for conveying the fluid. Dirt can also cause corrosion and damage to pipe materials. Serious will cause pipeline rupture, transport fluid leakage caused by loss, and even cause production suspension. The pollution and corrosion of pipeline is often the main cause of great harm to the economy and safety of pipeline transportation. With the increase of pipelines, pipe age increase, and pressure increase, running, taking, dripping, scaling, corrosion, plugging and explosion accidents continue to appear. These faults of the pipeline will not only have a bad influence on normal production and life, but also cause irreparable loss to people’s lives and property, so it is necessary to clean the pipeline regularly. Various methods can be used to clean the pipeline according to the specific situation of scaling. For example, the pipeline can be cleaned in a closed circuit with an aqueous solution of chemical agents such as acid, alkali, or surfactant, or the dirt can be peeled off from the pipe wall by ultrasonic wave, water jet, or other physical methods. However, it is a simple, low cost and effective method to clean the pipe with a pig in the early stage when the scale is light.

Composition of pigging equipment

Pigging equipment is one of the equipment needed in pipeline construction

Its functions include:

1. Pigging to improve pipeline efficiency;

2. Measurement and inspection of pipeline circumferential deformation, such as bumps;

3. Deformation;

4. Inspect all damage to the pipe metal from the inside, such as corrosion;

Remove liquid buildup and impurities from new pipelines after conducting tightness tests.

The design and installation of pigging equipment should meet certain operational requirements, such as the size and structure requirements of pigging detectors. And should follow the relevant design specifications to ensure its adaptability and safety.

As shown in the picture, the pig transmitting and receiving device is usually a horizontal structure with an inclination relative to the horizontal plane. The pig transmitting device is +5, while the pig receiving device is 15, which facilitates the loading and unloading of the pig. When designing the pig transmitting and receiving device, it is necessary to be equipped with a safety valve, pressure gauge, air outlet, sewage outlet, and other instrument ports so that the device can operate normally and the working condition of the device can be observed. The length of the main simplified is usually determined by the number of pigs and the length of the pig, with quick-opening blinds at the main simplified entry.

(a) Serving device

1- Ball box 2- Block valve 3- Line main valve 4- Through ball indicator 5- Balance valve 6- Balance pipe 7- Cleaning pit 8- Vent pipe and pressure gauge

(b) Ball-collecting device

1- Receiving cylinder 2- Block valve 3- Line main valve 4- Balance valve 5- Balance pipe 6- Blowdown valve 7- Blowdown pipe 8- Through ball indicator

Risk analysis and countermeasures of natural gas pipeline pigging operation

Pigging operation is needed in order to clean up sundries, liquid accumulation, and fouling in long-haul natural gas pipelines, improve pipeline transportation efficiency, reduce friction loss and pipeline inner wall corrosion, and extend the service life of pipelines. Because natural gas is inflammable and explosive material, long-distance pipeline operation pressure is large, Pigging may occur when the pig operation, pipeline sediment, and dirt block the pipeline, and for other reasons, pigging operation risk is high. In order to ensure the safety of the pigging operation, it is necessary to determine all possible dangers in advance and make appropriate emergency preparations to prevent the occurrence and expansion of accidents to the maximum extent.

Pig stuck

Pigging can be caused by pipe deformation, elbow radius less than the minimum radius allowed for pig passage, excessive water, dirt in the pipe, or large obstacles preventing the pig from moving forward. After the pig is stuck, the back pressure continues to rise and the front pressure continues to fall. Pipeline flow drops, leading to blockage of the whole pipeline, with serious consequences. Countermeasures: Firstly, the method of “increasing pushing pressure difference” is adopted, which can be achieved by increasing the upstream pressure of the stuck point or reducing the downstream pressure of the stuck point. Among them, increasing the intake of gas can increase the upstream pressure of the stuck point, but it should ensure that the pressure behind the pig does not exceed the maximum allowable working pressure of the pipeline. If this method cannot release the card, the gas behind the pig can be discharged and the pig can be released by pushing back. If the blockage is not solved, empty the stuck pipe segment, then cut the pipe and remove the pig.

Pig channeling

If the running time of the pig is more than 2 times of the theoretical running time under the normal pressure difference, or the calculated running distance of the pig is much larger than the actual running distance, it can be judged as pig channeling. Pig channeling causes pig wear, air leakage, pig scratch, rupture, or stuck in the inlet and outlet tee, etc. Countermeasures:

(1) Increase the gas intake behind the ball, reduce the natural gas pressure in front of the ball, and increase the pressure difference to start the ball.

(2) The pig stops running for more than 24h, if the whole line does not hold pressure, then send a slightly larger polyurethane foam pig with interference, and launch the shutdown pig, if the pig still cannot be received, analyze the reason for the pig gas channel, and determine whether to continue the pig.

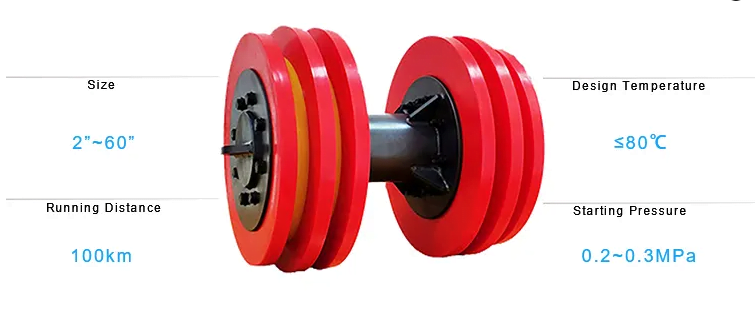

bidirectional pipeline pig

Reviews

There are no reviews yet.