Description

Significance of corrosion monitoring

Once oil and gas pipeline failure occurs, it may cause oil and gas leakage, which will not only have a disastrous impact on the ecological environment but also affect normal production and life, causing great losses to human life and property. Due to the large randomness of pipeline failure factors such as third-party damage and mechanical damage, it is not easy to monitor and prevent, so it is very meaningful to monitor the corrosion of submarine pipelines.

Corrosion monitoring technology is one of the important means to prevent pipeline accidents caused by corrosion. It is developed from nondestructive testing technology of equipment and corrosion test methods in the laboratory. During the operation of the device to be monitored, the corrosion state of the sample is continuously measured to discover the corrosion phenomenon without affecting the normal operation of the device to be monitored, and then reveal the corrosion process, understand the corrosion control effect, judge the corrosion state, accurately predict the hidden danger, so as to form a solution to the corrosion problem. In recent years, a series of corrosion monitoring technologies have been developed internationally, and a variety of methods have been formed, which have the following practical functions in production and life:

Real-time online monitoring of the corrosion status of equipment, timely grasp of the corrosion process, and preventing the occurrence of corrosion-induced equipment failure accidents;

According to the corrosion monitoring data, real-time adjustment of equipment operation parameters that need to be changed, such as the injection amount of corrosion inhibitor in oil pipelines, can realize scientific and reasonable control, convenient management, and automatic and intelligent decision-making when effective corrosion information is obtained by monitoring;

Effective online corrosion monitoring can improve the operating environment of the equipment, make the engineering equipment run in good working condition, extend the service life of the equipment, improve the use efficiency of the equipment, reduce the economic loss caused by overhaul, and improve the profit margin;

Long-term corrosion monitoring can obtain equipment use information base, so as to predict the service life of equipment, provide a scientific basis for equipment maintenance and replacement, and avoid production losses.

Monitoring principle of corrosion probe corrosion monitoring system

The measuring principle of corrosion probe: In corrosive media, as a measuring element of the metal wire is corroded, the length of the metal wire is unchanged, the diameter decreases, and the resistance increases, through the change of resistance test to convert the corrosion thinning amount of the metal wire, and then represents the corrosion amount of the wall thickness.

Corrosion probe suitable for humidity

Low temperature:0-120℃ Applicable pressure range:≤20Mpa

High temperature:120℃-450℃ Applicable pressure range:≤2.0Mpa

Applicable occasion: Electrolytes and non-electric | solutions for all kinds of corrosive medium.

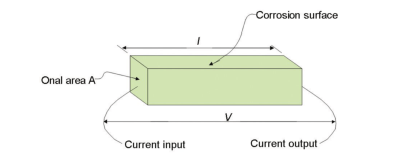

The corrosion products (such as metal oxides, etc.) produced in the process of metal corrosion are mostly non-conductive substances. If a current is applied to a sheet of metal, the thickness of the energized sheet will decrease as the corrosion progresses, thus increasing its current resistance. The corrosion probe technique is used to obtain corrosion loss and corrosion rate data by measuring the resistance change of the metal test piece during corrosion. This corrosion probe is also known as the electronic mount. As a sensitive element exposed to the environment to be monitored, the basic principle diagram of the corrosion probe for corrosion monitoring is shown in FIG. 1.

As shown in the figure, during the monitoring process, one side of the metal test piece is exposed to the environment to be monitored, and a current is injected into the metal test piece. According to the calculation formula of metal resistance, the initial resistance of the metal test piece is:

R=P 1/A

Where p is the conductivity of the metal test piece, R is the resistance of the metal test piece, A is the current cross-sectional area of the metal test piece, and 1 is the length of the metal test piece.

As the corrosion progresses, the current cross-section A of the metal test piece decreases, and the resistance R increases according to formula (1). By monitoring the change of its resistance value, the corrosion thickness change can be deduced according to formula (1) to obtain the corrosion loss and corrosion rate information.

Corrosion probe corrosion monitoring products and applications

In the actual corrosion monitoring work of a corrosion probe, a complete corrosion monitoring system includes a corrosion probe, data collector, communication converter, workstation, and other components.

The corrosion probe is a sensitive element exposed to the corrosion environment to be monitored. The metal test part of the corrosion probe changes with the corrosion. The data collector, the corrosion monitor, will apply constant current to the corrosion probe and monitor its resistance change. The communication converter will perform simple data processing and transfer the data to the terminal’s server or client. The workstation will receive, store, back up, and analyze the data, and finally present the data to the monitor in a simple and understandable form.

Install

Generally, it is recommended to install in bypass, sideline, or other switchable positions at high temperatures, which can reduce the probability of accidents and increase the safety factor. The selection, material, type, and environmental parameters of short connections, flanges, and valves in the installation process should be consistent with the pipeline design standards.

corrosion probe

Reviews

There are no reviews yet.