Description

The corrosion probe is actually a probe equipped with a metal test piece. The main advantages of corrosion probe corrosion monitoring technology: are simplicity, sensitivity, and strong applicability (can be used in any medium).

The temperature in the working area is basically constant, so it is insensitive to both temperature difference potential and contact potential. In recent years, corrosion probe corrosion monitoring has been applied more and more in high voltage systems, and oil and gas transmission lines with large temperature variations in the monitoring area, The temperature difference effect caused by the contact potential inside the corrosion probe greatly interferes with the corrosion monitoring results. In order to improve the accuracy and stability of natural gas high-pressure pipeline corrosion monitoring and accurately evaluate the corrosion trend of natural gas pipelines, It is necessary to eliminate the error caused by contact potential on corrosion monitoring. Therefore, the research on the corrosion probe corrosion monitoring instrument focuses on the influence degree of temperature on measurement results and the principle of temperature compensation. The accuracy and stability of the corrosion probe measuring instrument can be judged through laboratory tests at different temperatures and comparisons with weight loss and electrochemical polarization methods.

The online corrosion monitoring system works according to the following process

*

If the state change of the corroded pipe is uniform, the change of the resistance value of the corrosion probe increases in proportion to the increase of the corrosion depth of the pipe. Rather than being used more frequently than other corrosion monitoring methods, corrosion probes are uniquely adapted to water vapor, gases, soil, wet carbohydrates, and non-electrolytes of insoluble liquids in harsh or intermittent electrolytes.

Corrosion monitoring probes are used to measure the loss of corroded or eroded metals by electrical resistance. This method is used in virtually any environment except for liquid metals and some conductive molten salts. Corrosion monitoring probes based on resistance measurement can directly measure the amount of metal loss. Metal loss and corrosion rate can be plotted as a function of time, and the slope of the curve is the average corrosion rate of metal corrosion in the selected time interval.

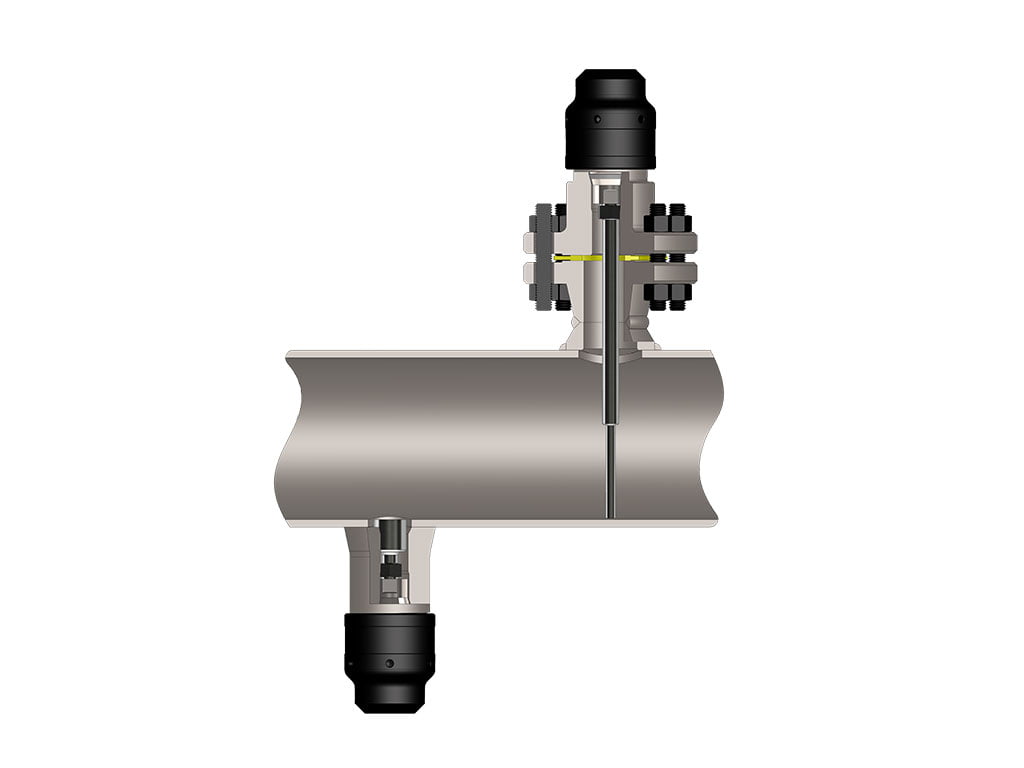

The sensing element of a corrosion probe

The sensitive element of the corrosion probe is the key to measuring the corrosion rate. The probe element is composed of a variety of alloys. Understanding the type of each probe, selecting the most suitable form of the probe element and the unique sensitivity of the probe are important ways to obtain excellent corrosion data. The shape design of the sensitive element can be divided into the following types:

Bar type, tube type, line type probe element

These components are generally more economical and use a wider range of alloys than other components. Both test and standard forms of element face seals are used, and the standard element is built into the probe to protect against corrosion. Glass-metal encrypts enhance seal integrity and are generally suitable for pH 0-9 fluids and temperatures up to 500 degrees Fahrenheit. They are generally not suitable for use in solutions containing fluoride ions, which can corrode glass, ceramics, and epoxy resins on the seals. Teflon and ceramic have become the main filling types in corrosion probes.

Cylindrical element

The elements of these probes are welded directly to the probe itself, providing the most complete seal in corrosive environments. The wide surface of the measurement is the fastest to respond dynamically to the transient effects of temperature and is very sensitive to the effects of conductive sediments such as iron sulfide. Its structure enables the probe to be applied in the PH range of 0-14 and temperatures up to 500 degrees Fahrenheit (260 degrees Celsius). The cylindrical probe element and the probe itself are made of the same alloy structure to prevent corrosion current from affecting them.

corrosion probe

Reviews

There are no reviews yet.