Description

Low-temperature Corrosion probe series

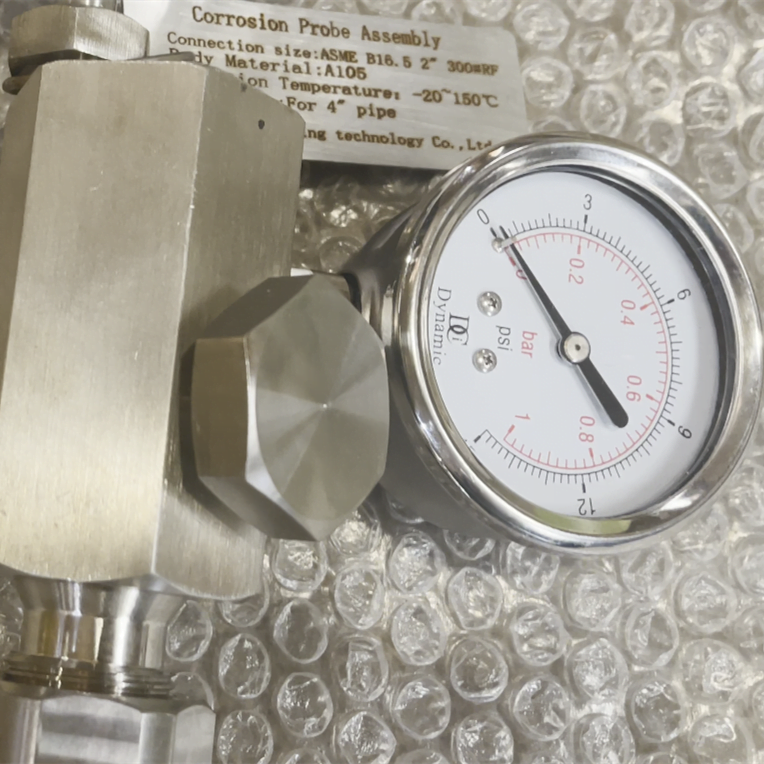

Low-temperature Corrosion probes can be divided into telescopic low-temperature Corrosion probes and non-telescopic low-temperature Corrosion probes according to the disassembly method.

Retractable low-temperature Corrosion probe

Model: ERLK- Material – Useful life (URO.25 can be omitted)- order length

Technical parameters:

Probe material: Optional

Applicable environment: temperature ≤240℃, pressure ≤2.0MPa

Probe wire diameter: 1 mm

Probe life: When the corrosion rate is 0.125mm/a, ≤ 4 years

Probe length: Standard length of 900 mm, which can be increased by a multiple of 100 mm.

Non-telescopic cryogenic Corrosion probe

Technical parameters:

Probe material: Optional

Applicable environment: temperature ≤240℃, pressure ≤20.0MPa

Probe wire diameter: 1 mm

Probe life: When the corrosion rate is 0.125mm/a, ≤ 4 years

Probe length: Standard length of 900 mm, which can be increased by a multiple of 100 mm.

High-temperature Corrosion probe series

Retractable high-temperature wire Corrosion probe

Technical parameters;

Probe material: Optional

Applicable environment: temperature ≤430℃, pressure ≤3.0MPa

Probe wire diameter: 1 mm

Probe rod diameter: 20 mm

Probe life: When the corrosion rate is 0.125mm/a, ≤ 4 years

Non-telescopic high-temperature wire Corrosion probe

Technical parameters:

Probe material: Optional

Applicable environment: temperature ≤200℃, pressure ≤3.0MPa

Probe wire diameter: 1 mm

Probe rod diameter: 20 mm

Probe life: When the corrosion rate is 0.125mm/a, ≤ 4 years

Probe mounting length: 200mm~450mm(length from flange sealing surface to probe head)

Principle of resistance corrosion probe

The corrosion probe monitoring method is a kind of online continuous monitoring device. It can continuously detect the corrosion rate inside the pipeline when the fluid changes. Most offshore oil and gas fields are installed with Corrosion probe online corrosion monitoring devices 3. The corrosion probe method is one of the most widely used corrosion monitoring methods in the petrochemical industry, and this method is relatively mature. The Corrosion probe method mainly uses a probe of the same material as the equipment and pipe being measured, and a compensation test piece of the same material is built in as the reference electrode. The principle is to calculate the corrosion rate of metal in a process medium by measuring the change of resistance value of the metal element in the process medium. When a metal element is subjected to corrosion in the process medium,

The cross-sectional area of the metal decreases, resulting in a corresponding increase in resistance. The increase in resistance is directly related to the metal loss, so the corrosion rate of metal can be reduced by a certain formula. This technology, which began in the 1950s, can be used in a variety of media, and the monitoring period is usually a few days. The Corrosion probe has the advantages of simple and rapid measurement, fast signal feedback, and is not affected by a corrosive medium. In addition, the Corrosion probe can reflect the corrosion trend in time during equipment operation.

Generally speaking, an online corrosion monitoring system mainly consists of a probe, corrosion data acquisition and transmission system sensor, data recorder, portable or continuous data download corrosion monitoring instrument, and data processing system. The probe is installed at different monitoring points and connected with the data acquisition and transmission system installed in the field. The data acquisition and transmission system collects the original analog signals related to the rot rate, converts them into digital signals after amplification, and sends them to the data processing system, such as the computer in the monitoring room). After the data reaches the computer, it is processed, and displayed, and a database is established. Save, and download to a computer for analysis and storage.

Corrosion monitoring point

Under the condition of not affecting the normal production of the station yard, in order to enable the installed corrosion monitoring equipment to better monitor the corrosion rate of the pipeline, the probe should be installed on the:

(1) Pipelines with high hydrogen sulfide and carbon dioxide content in oil and gas pipelines;

(2) Pipe section with free water and condensate water;

(3) More important sections in daily management;

(4) Pipelines considered to be seriously corroded in daily management:

(5) Downstream pipe section with specific corrosion prevention measures, such as corrosion inhibitor filling station, etc.

(6) Platform riser;

(7) Downstream of the injection point of chemical agents;

(8) The oil outlet line (flowline, downstream of the chemical injection point) at the wellhead;

(9) The inlet of the primary separator and test separator;

(10) Water outlet pipeline of each stage separator;

(11) Gas outlet pipeline of each stage separator;

(12) Gas outlet pipeline of seawater cooler;

(13) Air float scrubber separator production water outlet pipeline

(14) Air float scrubber selector gas outlet pipeline;

(15) Downstream of the degasser of the water injection system;

(16) The downstream of the water injection pump in the water injection system is close to the water injection manifold.

corrosion probe

Reviews

There are no reviews yet.