Description

The resistance probe is the sensing unit of the resistance corrosion monitoring system. It provides you with probes suitable for different temperatures, pressures, and disassembly conditions according to different industrial site environments. Resistance probe temperature 430℃, pressure 20MPa. In order to avoid measurement error caused by the change of medium temperature, the temperature compensation element is placed inside the probe and connected with the measuring element in the circuit, the influence of temperature can be completely eliminated. During the measurement, the corrosion thinning amount is calculated by using the resistance ratio between the measured element and the temperature-compensating element before and after corrosion. The resistance ratio before and after corrosion can also be regarded as the resistance ratio of the first measurement and the second measurement. For metal test pieces of different shapes, the calculation formula of corrosion thinning amount is also different. The sensitivity of the wire measuring element is improved compared with the sheet measuring element under the same life condition, so the wire measuring element is often used for the resistance probe.

Common material:

Carbon steel,304SS,304LSS,316LSS

Applicable temperature;≤240℃

Applicable pressure:≤2MPa

Measure the thickness of the test piece:0.25mm~0.5mm

Probe safety life:≤ 4 years

Probe length: Optional

Installation mode: DN40 and above valves, valve connection; Taper pipe threaded connection; Flanged thread short connection; Fixed flange connection can be customized according to the working condition;

Pipeline corrosion online detection solution

On-line corrosion monitoring system

(1) Can identify the high incidence area of corrosion, can carry out real-time monitoring and evaluation of media corrosion, prevent the occurrence of accidents, reduce the uanplanned stop, provide a basis for scientific management and decision-making, ensure the needs of safety management;

(2) To predict the equipment life, maximize the operation cycle, maintain the technical integrity of the production unit to avoid environmental pollution, avoid third-party damage and accidental production delays, and ensure economic benefits;

(3) It is helpful to analyze corrosion causes, understand the relationship between the corrosion process and process parameters, optimize process anticorrosion schemes, or evaluate the actual effects of some anticorrosion methods.

The basic composition of the system is as follows:

Corrosion probe, PH probe and thickness probe, data collector and thickness node, data communication converter, server, and special operation kit, etc.

Function introduction:

(1) Corrosion monitoring data, temperature, pressure, and other data are packaged into the server

(2) Separation, extraction, conversion, processing, and analysis of corrosion monitoring data

(3) Update data curve in real time

(4) Draw curves of metal loss and corrosion rate

(5) Point-to-point corrosion rate calculation

(6) Real-time data detection

(7) Event log recording

(8) Archive and input data

Characteristics of corrosion probes

Simple operation, reliable data, strong practicability.

Flexible and convenient installation.

Simple structure day turn

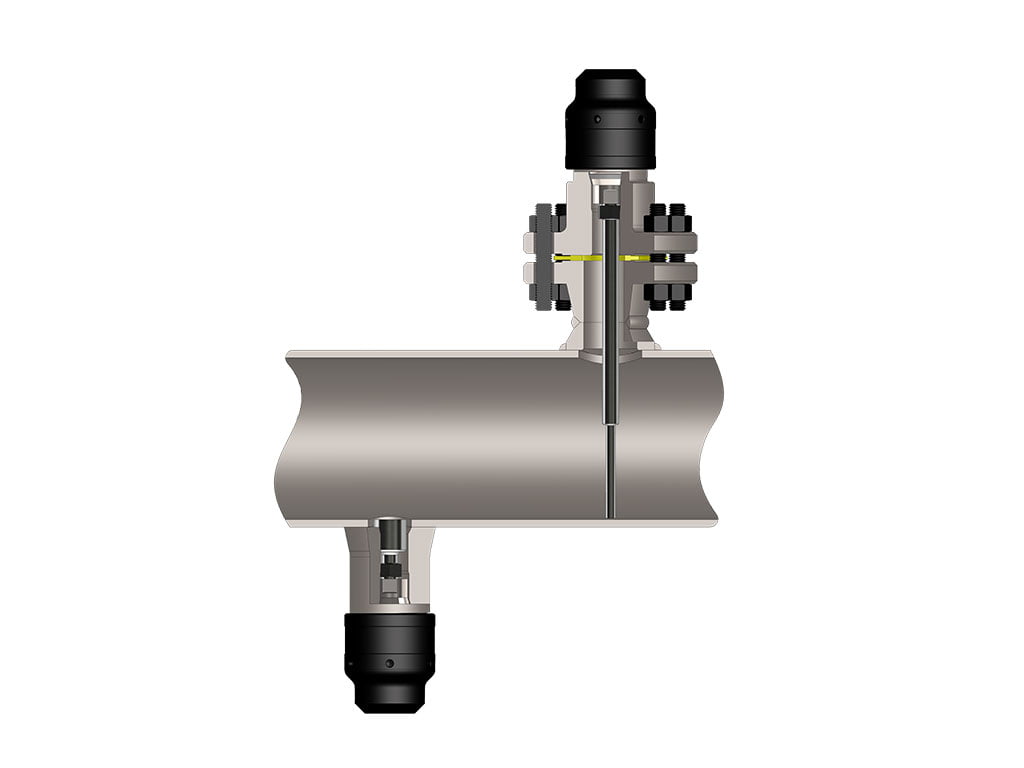

Corrosion probe structure

Probe rod: The lower thread is used to connect the probe, the upper outer thread is used to connect the carrier top inner thread is used to connect the transmission cable

Corrosion probe 1 Probe: used to detect the corrosion condition and connect with the probe rod thread 3 Corrosion probe carrier: the structure is the same as the mounting carrier 4 Junction box: the upper electric mode line is used to connect the probe rod, and the manufacturer’s battery and data acquisition system is provided inside 3 Data collector: the non-installed component of this part is used for temporary access to the junction box when Party A’s staff collect data

Application principle of corrosion probe

The application principle of the corrosion probe is to induce the corrosion of the medium in the probe part to the distribution box through the electric olive, by the data collector! The reaction shows corrosion

Corrosion probe installation.

The process of installing the carrier is the same as that of installing the mounting carrier. The probe and probe are connected and tightened. The probe and probe are vertically inserted into the carrier and inserted into the thread for rotation and tightening

There are two ways to install fixed piles:

Method 1: Select a 3-inch pipeline of 12 meters, insert and weld a thin steel plate in the upper center according to the size of the junction box, drill holes above the steel plate for installing the junction box, and the size and spacing of the holes correspond to the connecting holes at the back of the junction box. The lower part of the pipeline is 700mm deep underground and the upper part is 500mm high above the ground. The whole pile anticorrosive coating construction. The above part of the coating structure is coated with the steel structure on site, the lower part is coated with epoxy asphalt paint, and the lower thickness is coated with the surface derusting grade Sa2.5 as required on site

Method 2:3 inches of the pipeline is also selected, the lower part is fixed with C30 concrete, and the upper part is 500mm high above the ground. The combined coating structure is the same as method 1, but the part of the concrete does not need to be a Changfu cold This surface pen grade Sa25 silver

The back of the junction box is fixed on the pile with a single screw, the upper electric mode is directly inserted into the top of the probe rod, and the connection is tightened with thread.

Corrosion probe detection

The detection time of the probe is generally 2 months, and the corrosion status is directly reflected on the data collector.

corrosion probe

Reviews

There are no reviews yet.