Description

Feature

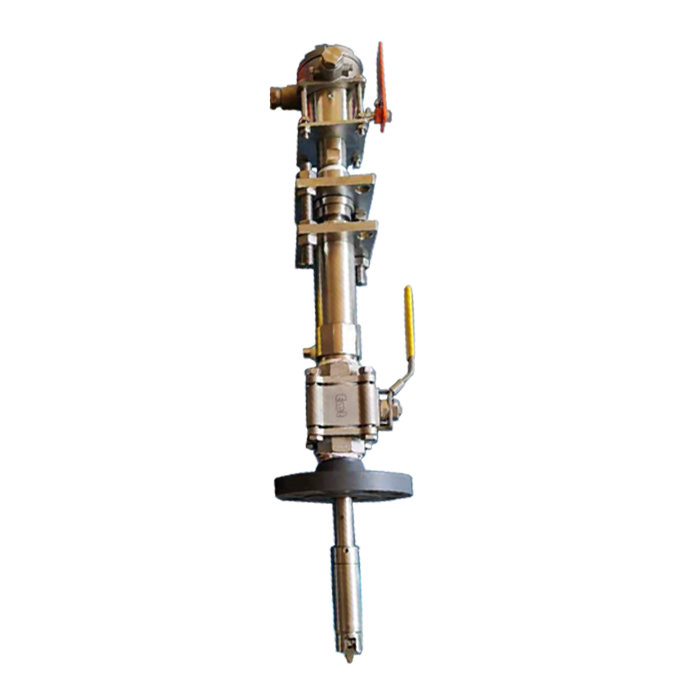

Explosion-proof grade: EXdll BT4

Protection level: IP65

Corrosion protection grade: WFI

Remote signal appearance hole thread: 1/2NPT

contact capacity: 24V DC.3A

Electrons pass through the indicator

Our intelligent electronic ball indicator overcomes the old false positives caused by the interference of external magnetic field lines. With a double probe structure, the external magnetic force line interference can be ruled out by itself when working, with a large receiving range and high response speed, and with the pickup memory function and sound and light alarm display mode, so that the pig alarm is accurate when passing.

Using dry battery power supply, a continuous working time of 72h

Receiving radius: 15m

Response speed:30m/s

Effective detection depth: 2m

Electronic positioning receiver

The electronic positioning receiver is mainly used to detect the operation of the pig and find the location of blockage accurately. It has a strong shockproof ability and can resist the interference brought by walking vibration without an alarm display. It is small, easy to carry, and easy to use in the field and at night.

Using a dry battery power supply, continuous operation for 72h

Receiving radius 12m

Response speed 30m/s

Effective detection depth: 8m

Positioning accuracy: ±7cm

Pig battery charger

The charger adopts voltage protection, when the pig lithium battery is fully charged, the voltage reaches the protection value, without personnel on duty, the charger will automatically power off. (Note: The rated charging voltage is 220v)

Special charger to charge

The pigging and supporting instruments produced by our company are powered by rechargeable nickel-cadmium batteries. The instrument must be charged before use and can be put into use after charging. The charging steps are as follows:

To charge the pig, clip the red chuck of the charger on the copper electrode column behind the pig, and the black chuck on the iron electrode column behind the pig, and plug in the power plug of the charger (220v).

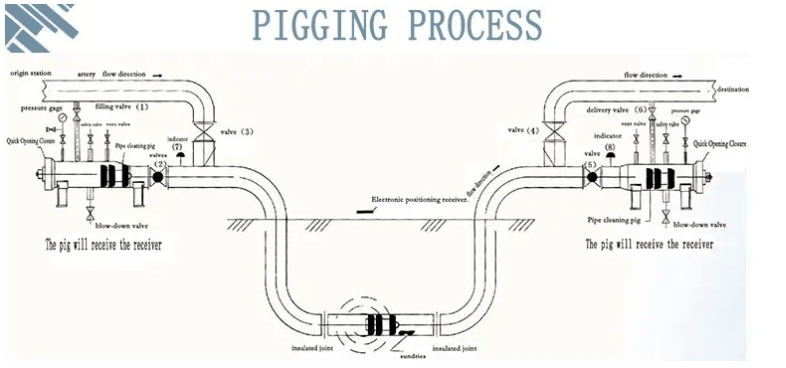

Pig workflow description:

1. Normal flow: pipe transport medium from the first station through valve 2 into the main line (valve 1, 3 closed states), through valve 5 into the end station.

2. Pig ball process: Check whether valve 1 and valve 3 are closed, open the quick-opening blind plate, push the pig into the reducer, tighten, close the blind plate, and open valve 3. Close valve 2 and fire the pig. After the pig is issued, open valve 2, close valve 3 and valve 1, open the blowdown valve to blow off and prepare for the next ball pass.

3. Pigging process: Check whether the ball collecting cylinder valve and pressure gauge indicator is in good condition, before the pig arrives, open valve 4, and valve 6, and close valve 5, after the pig shows the pig into the ball collecting cylinder through the indicator, open valve 5, close valve 4, valve 6, open the blowdown valve, empty the valve, open the blind plate when the ball collecting cylinder pressure is zero, take out the pig, close the blind plate for the next pig Get ready for the ball. At this point, the pig-pigging operation is complete.

4. Pig tracking and positioning operation: Due to the long distance between pigging lines, in order to track the operation of the pig, it is necessary to set several indicators along the pipeline to monitor whether the pig has passed or not. If the instrument at monitoring point 1 alarms, it means that the pig has passed this point smoothly, while the second point does not alarm. Indicates that the pig is stuck between points 1 and 2. At this time, the positioning receiver is used to look for the pig between points 1-2. The receiver receives the signal emitted by the pig, which is the location of the pig stuck.

Matters needing attention when using relevant instruments in the pigging system:

Use of pig:

Before the pig is used, it must be charged according to the method specified in the using method of the charger. After charging, the copper and iron electrodes are connected to make the transmitter work, and the receiver is used to receive whether the signal is transmitted. The receiver can be put into use after receiving the normal working signal of transmission (once a second).

Positioning operation of pig:

When the probe is perpendicular to the line axis, the maximum values of the two signals can be received at the front and rear points of the pig (the distance between the two maximum values varies depending on the depth of burial). During the positioning operation, the probe can be moved while the gain knob can be adjusted to make the pointer swing to about 80% of the dial when the signal is strongest. The handheld probe then looks for another maximum in front of or behind that maximum. After measuring the approximate location of the two maxima, Again in the middle of the two maximum positions to find the minimum value of the position, while looking for a site to increase the gain knob until the gain is adjusted to a large, the signal is very small, or no indication, the probe from this point forward or after the offset point can obviously see the table head pointer for regular swing. At this point, below the point not indicated by the watch hand is the pig stuck position. (Note: When looking for two maximum and minimum values, try to keep the distance between the probe and the ground constant) Maximum minimum Maximum value

Maintenance and maintenance:

All pressure vessels must be maintained and maintained in a timely manner after the water pressure test and acceptance, no matter whether before going out or after arriving at the site, so as to avoid undue consequences.

All containers arriving at the site shall be treated and maintained as soon as possible after the suppression, so as not to rust and cause unnecessary trouble to the site.

pig indicator

Reviews

There are no reviews yet.