Description

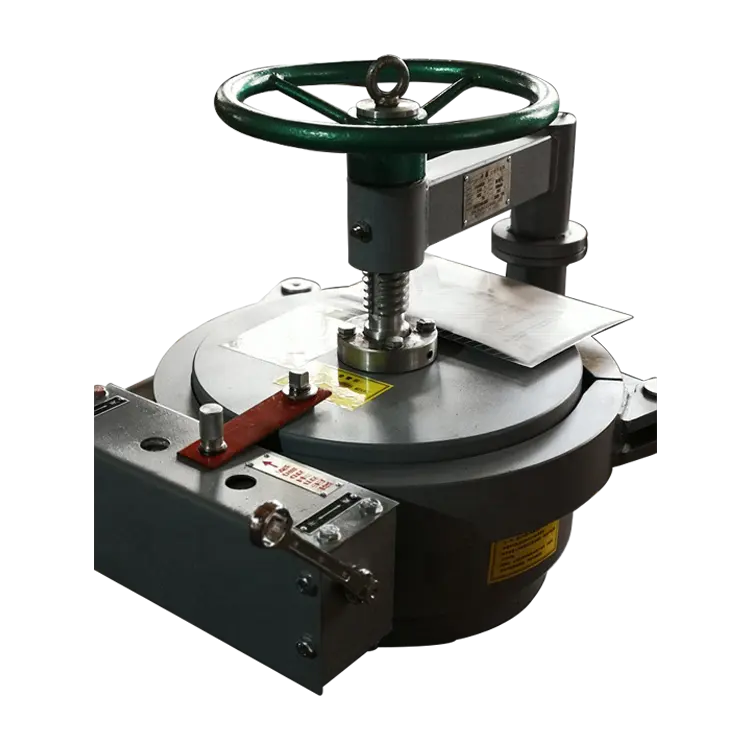

The quick opening closure is generally composed of a cylinder flange, head cover, hook ring or clamp, sealing ring, safety interlock mechanism, opening and closing mechanism, swivel arm and sub (when needed), and other components. The idea is to reduce the difficulty of opening and closing the end cover through a special structure, and reduce the time required for opening and closing the end cover, thus saving labor and improving production efficiency. The quick opening closure does not need to be sequentially removed and installed as the traditional bolt flange connection and only needs to move the lock case a short distance or rotate at a certain Angle to complete the opening and closing of the cover, even a worker can complete the operation in a relatively short time. A mechanical device used in the circular opening of a pressure pipe or vessel to enable rapid opening or closing.

Function

The quick opening closure is an integral part of the receiver and receiver of the oil and gas pipeline pig, which is usually used in the tooth insert and lock ring. The structure feature of the snap-open blind plate, which has obtained the Chinese patent right, is that the connection between the simplified and the blind plate adopts an intermittent thread section, and the opening and closing are locked by the intermittent thread insert. The latch type has the advantages of a simple structure, good self-locking performance, and a light switch compared with the tooth insert type. Because the locking ring is not used to lock, there is no stress concentration problem of the locking ring, the switch is fast, the rotation Angle is less than 90°, saving time and labor, easy operation, and reducing the cost by 20%.

The quick opening closure is mainly used for the receiver, the end cap of the service cylinder, and the end cap of the filter on the crude oil and natural gas gathering and transportation pipelines that need to be switched quickly. It can also be used for the pipelines or containers that need to be switched frequently in petroleum, chemical, light industry, national defense, and water supply and drainage projects to replace the flange cover, which has the characteristics of good sealing, easy operation, quick switching and safe and reliable.

The quick opening closure is divided into two kinds: horizontal and vertical. Its main structure comprises a blind plate cover, cylinder, sealing ring, safety interlocking device, and opening and closing mechanism. The opening process is as follows: open the receiving and serving cylinder vent valve, so that the pressure in the cylinder is reduced to zero; Unscrew the safety screw and take out the locking plate; Push the booster rod in a counterclockwise direction. When the handle touches the opening stop pin, hold the lifting ring with your left hand and the handle with your right hand. Pull the blind plate cover out of the cylinder and turn it to the left, then the blind plate cover will be opened. If the opening torque is not enough, you can first turn the starting screw to loosen the blind plate cover. The closing process is: after thoroughly cleaning the sealing surface, threads, and sealing slots, apply anti-rust grease; Hold the lifting ring with the left hand and the handle with the right hand, align the blind plate cover with the cylinder and push it into the cylinder; Push the afterburner in a clockwise direction until the handle touches the closing stop pin; Install the release plate and screw on the safety screw, then the closing process is complete.

Quick Opening Closure Product features

1. Check that the indicators on the container are normal.

2. Check that the connecting parts of the container and the quick opening closure do not leak;

3. Necessary explosion-proof tools, fire extinguishers, fire MATS, and other facilities are ready;

4. The operation of opening and closing the blind plate shall be carried out by one person and supervised by other personnel;

5. During the opening and closing operation, the front of the quick opening closure cannot stand.

6. Opening steps

7. Check the pressure in the chamber of the blind plate cylinder. If the pressure indicates that the value is not returned to zero, no operation is allowed

8. Check whether the container inlet and outlet valve are completely closed without any source of pressure

9. Slowly loosen the pressure alarm bolt and check whether there is pressure in the container

10. If there is no pressure, remove the pressure alarm bolt and its locking disc from the blind plate

11. Turn the handle 60-120 degrees counterclockwise to start the drive chain and the mechanical device to open the blind plate

The quick-opening closure comprises a blind plate cover, a cylinder flange, a safety interlock device, an opening and closing mechanism, a supporting frame, etc. The safety interlock function of the blind plate is composed of a safety lock plate and a pressure relief device (the blind plate is self-locking, shock-proof, anti-loosening, and can be opened for secondary pressure relief).

Reviews

There are no reviews yet.