Description

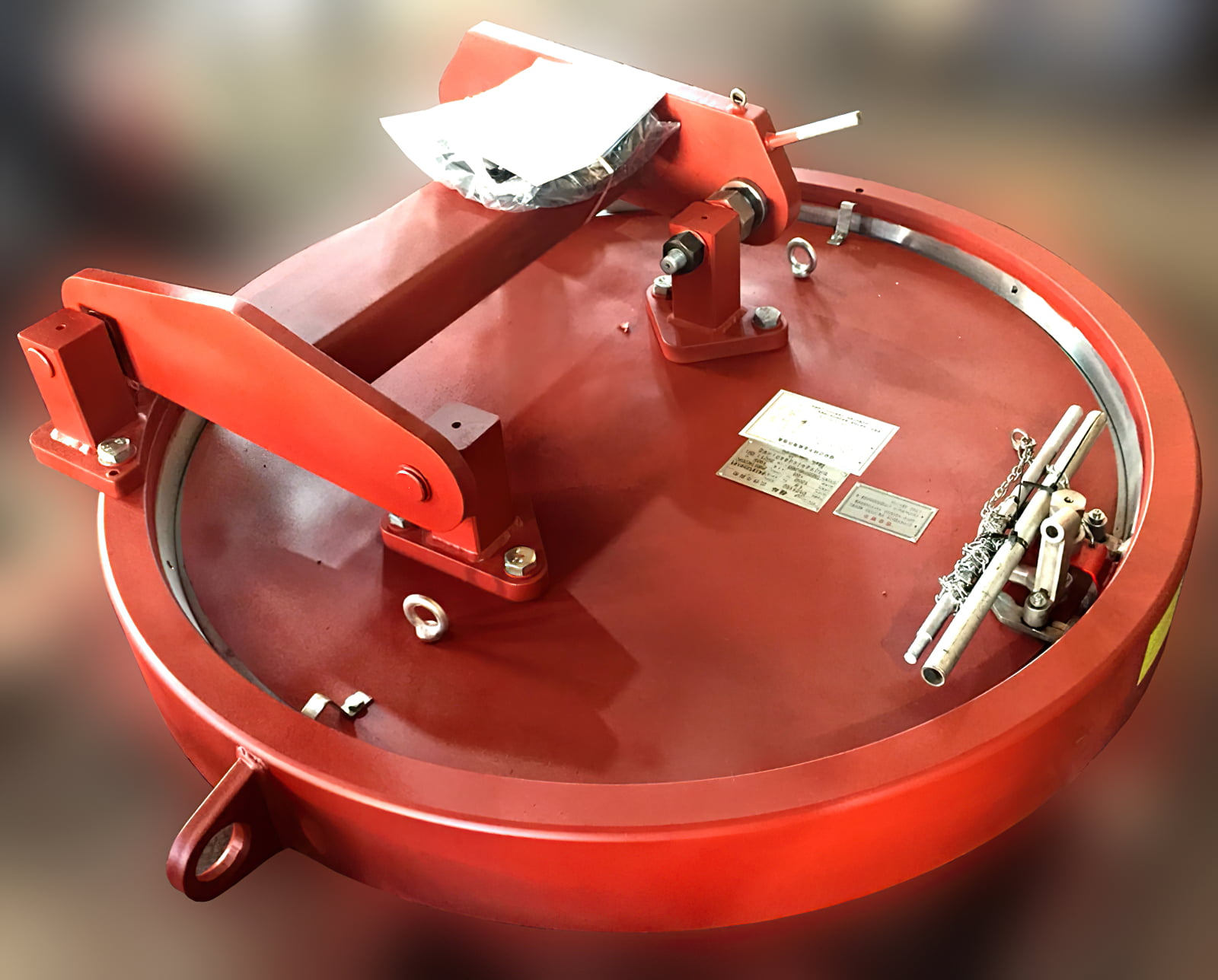

The quick opening closure adopts the ring lock structure. The lock ring is composed of a large section and a small section. The small section of the ring lock and the manual pressure alarm device, namely the pressure relief bolt, always becomes a whole. During operation, if the door of the blind plate does not reach the predetermined closing position, the large section of the lock ring will not be stuck in place, and the small section of the lock ring which is integrated with the pressure relief bolt assembly cannot be installed in neutral, the pressure relief bolt cannot be screwed in place, and the container cannot be operated with pressure boost to achieve the purpose of safety. After the lock ring is in place, turn the handle counterclockwise to start the drive chain and the horseshoe mechanism, and the door can be rotated by hinges

Structure

Clasp lock

Dual-phase stainless steel clasp makes 360 degrees of uniform compression, conical thrust ring inclined stuck between the door and flange so that the lock ring is not subjected to shear force;

The clasp type is an external lock, locking state operators at a glance, in full compliance with ASME standards, providing 100% security;

Ring lock is easy to operate, only need to retract or expand the locking belt, and zero failure;

Since the lock ring is external, the GD door should be light in weight.

Type

Horizontal and vertical

According to the needs of practical application, GD provides two kinds of horizontal and vertical. The horizontal opening mode is left or right rotation through the door shaft, and the vertical opening mode is lifting up and translating through the davit. The other two kinds of structures are the same.

Pressure alarm

The pressure alarm device is integrated with the small section of the lock ring

The purpose of the integrated design is that in the case of residual pressure, the pressure alarm device, namely the pressure relief bolt assembly, is not removed so that the small section of the integrated lock ring can not be removed, the large lock ring can not be retracted, and the door can not be opened. It’s an interlock for safety.

Seal

Rubber and stainless steel springs are manufactured as one

Flange

Because the flange near the door bears pressure, the design flange is very thick, and never deforms after heat treatment;

Operation method

Opening of the blind plate

Check that the container inlet and outlet valves are completely closed.

Open the vent valve for vent and observe until the pressure reaches zero.

When FeS powder or sediment may exist in the equipment, clean water of about 10% of the equipment volume should be injected into the equipment through the pressure gauge discharge valve on the equipment or pipeline, and wet operation should be carried out. After the wet operation, the container can be put into operation again after being dried and qualified.

Slowly loosen the screws and check whether there is pressure in the container

Make sure the lock ring glide surface is clean.

Screw the pressure relief bolt. If residual pressure is indicated, tighten it again and wait until it is confirmed that there is no residual pressure.

Turn the handle 180 degrees counterclockwise to start the drive chain and horseshoe mechanism and gradually retract the lock band to the door groove

Then remove the omnidirectional handle and use the door hinge handle to rotate the door.

Blind plate closing

Check that the sealing ring is intact and installed in the correct direction.

Ensure the sealing and sealing surface and sealing groove are clean.

Grease the sealing groove, sealing surface, and lock ring sliding surface.

Push the door forward gently. When the edge of the lock ring touches the door shaft, push the door into the blind neck.

Push the door forward gently. When the edge of the lock ring touches the door shaft, push the door into the blind neck.

After confirming that the door is in place, insert the handle into the drive connection and turn it clockwise 180 degrees.

Ensure that the gasket of the pressure relief bolt is intact, and install the lock ring and the pressure relief bolt assembly.

Maintenance

Daily inspection of quick opening closure

Routine inspection

Check whether the lock ring and lock ring lug are deformed and whether the support clips are correctly installed

Check that the sealing surface of the door is clean and free of mechanical damage and corrosion

Check that the contact surface between the door and lock ring is clean and free of rust

Check whether the contact surface of the door and lock ring is clean and free from corrosion

e-check that the screw buckle of the pressure relief bolt hole is intact and free from corrosion

Check whether the sealing surface of the pressure relief bolt is damaged

Remove the lock ring to check whether the door is centered. Changes within 0.2mm are allowed

Seal performance inspection

Test with a pump suction detector through the drainage hole at the lower part of the quick opening closure. After the probe is extended into the drainage hole and the pointer is kept stable for more than 3 minutes, the reading is done. If the pointer of the detector is not offset, it indicates that the blind plate is well sealed

If the pointer of the detector is offset in the previous step, seal the drain hole. 20 minutes later, use the pump-type detector to detect the chain edge around the blind plate and observe whether the pointer is offset. If so, keep the probe in the pointer drift position for one minute and then read

Maintenance check

Inspect door seals for damage

Whether the door is in the middle of the neck at all times

quick opening closure

Reviews

There are no reviews yet.