Description

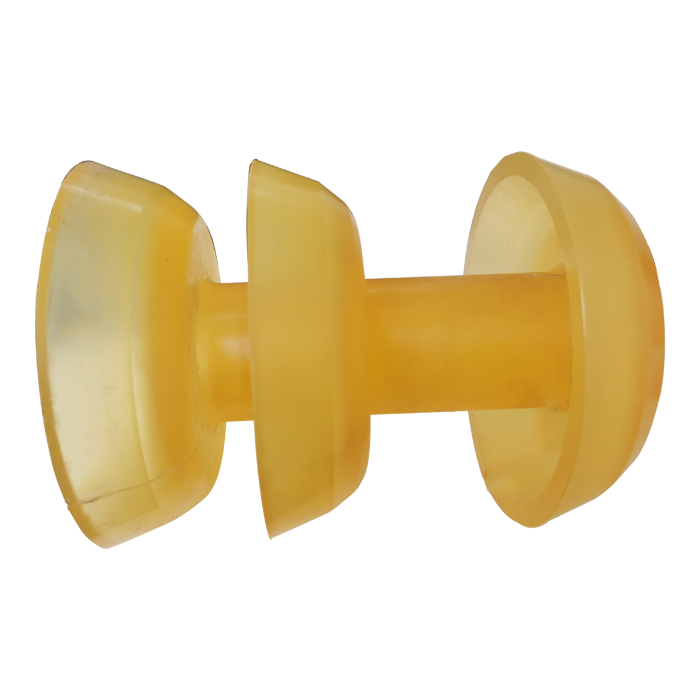

The definition of polyurethane pigs

Polyurethane pigs can form multiple sealing surfaces with the pipe wall, which has the function of scraping, sealing, and isolation. The advantage of this polyurethane pig is that it is lightweight, flexible, and can pass through a bend with a small radius of curvature. And because the pig is flexible, the impact on the pipeline is relatively small.

How the polyurethane pigs work

The working principle of polyurethane pigs is to put the pig into the pipe so as to form a seal. The pressure difference formed before and after the pipe transport medium is used to push the pig forward. Because the pig has a certain interference amount to the diameter of the pipe, the purpose of removing debris and wax accumulation of water in the pipe is achieved.

Pigging time or cycle

Pipeline pigging can ensure the safety and economy of pipeline operation, but frequent pigging will also bring unnecessary waste of manpower and material resources and operational risks. The pigging period is generally determined by the calculation of gas transfer efficiency. For example, the pigging cycle of the gas transmission pipeline in the Sulige gas field is calculated by the Panhanter formula to obtain gas transmission efficiency. Pigging treatment is carried out when the gas transmission efficiency is lower than 90%.

Pigging characteristics of different conveying medium pipelines

Crude oil pipeline

Under the same conditions, the wear of pigs on crude oil pipelines is much less

then that on the gas pipeline. The pigging of crude oil pipelines is mainly waxy crude oil pipelines to be pigged regularly. The main purpose of pigging waxy crude oil pipelines is to remove the wax deposited on the wall. The wax deposited on the pipe wall will reduce the effective flow area of the pipeline and the oil flow diameter of the pipeline, which will increase the energy consumption between stations. In severe cases, the tube may be coagulated. Therefore, in order to ensure the normal and safe operation of the pipeline, regular pigging is required for waxy crude oil pipelines. Soft pig and mechanical pig are mainly used to clean waxy crude oil pipelines. The pigging balls are fired into the waxy crude oil pipeline in the order of a soft pig followed by a mechanical pig.

Natural gas pipeline

The main purpose of gas pipeline pigging is to remove water from the pipeline. Because natural gas usually contains H2S CO2 and other acidic gases, it is easy to form a hydrate, which makes the pipeline. In order to remove water from the pipeline, a better-sealed straight pig should be used.

The characteristics of natural gas pipeline pigging are different from that of oil pipelines. For long-distance and large pipe-diameter gas pipelines, the gas pressure is generally about 10MPa, and the gas flow rate can reach about 10 m/s. Moreover, due to the strong compressibility of natural gas, the gas flow rate has a large fluctuation range. However, according to the research, the more stable the pig running speed in the pipeline, the better the pigging effect will be. If the speed is too fast, the pigging effect will be affected. In order to maintain the speed of the pig, reducing the gas flow will cause great economic losses. In addition, pigs with different speeds should be designed for different pipe diameters to improve the pigging effect. Therefore, according to the characteristics of natural gas pipeline pigging, it is necessary to design a pig that can control the speed. At present, the real-time speed of the pig is controlled by the speed-regulating device of the bypass valve.

The development trend of cleaning pig technology

A variety of pig functions can play a role such as cleaning debris, removing wax and water, and play a key role in ensuring the normal and safe operation of crude oil, refined oil, and natural gas pipelines. However, in the process of pigging operation with a pig, there will be a variety of problems that threaten the safety of pipeline operation. It will become the development trend of pigging in the future to solve these problems so as to make the pipeline safer.

1. The most important thing to avoid in pig-pig technology is the problem of pigging. The main reason for the blockage of the pig is that in order to clean the wax or debris on the pipe wall, the pig generally requires a certain amount of interference on the pipe and good sealing. However, when the pig passes through the elbow, if the radius of curvature of the elbow is relatively small and the bending of the pig spindle is not good enough, once more sediment accumulates in front of the pig, the pig will easily get stuck at the elbow. In this case, it is generally necessary to increase the flow of conveying fluid to flush out the stuck pig, but it may also produce serious consequences of blocking the whole pipeline.

2. The pigging effect of the pig is closely related to the running speed of the pig in the pipeline. If the running speed of the pig is too fast, the pigging effect will be affected, and the running speed of the pig depends on the pressure difference between the front and rear ends of the pig. How to maintain the proper pressure difference between the front and rear ends to control the speed of the pig has become a topic that needs to be further studied.

polyurethane pigs

Reviews

There are no reviews yet.