Description

Features of the 3-cup pipeline pig

The cup adopts the form of a flanged structure, and the wear capacity of the cup is increased by 30% on the basis of not increasing the interference quantity of the cup. The cup of the pig has enough flanged edge, thickness, and interference quantity to fully ensure that it will not be deformed due to its self-weight in the pipeline, and effectively avoid the negative impact of other auxiliary machinery on the pig’s passing ability and cleaning effect. The cup is made of polyurethane by molding. The surface should ensure luster, and no bubbles crack inside. The interference range of the cup relative to the inner wall of the pipes is 4-7%.

Through the optimized design of the 3-cup pipeline pig structure size, Meanwhile, the ability to push dirt off the pig is greatly improved, so the pig’s passing ability and scaling ability are greatly improved. In order to improve the wear resistance of the cup, the following two improvements are made: First, the wear resistance of the leather cup is improved by using the new imported material – polyurethane. Secondly, the structure of the cup is changed, the traditional dish-shaped cup is changed to a double-edged leather cup, which increases the contact area between the leather cup and the inner wall of the pipe by 30%. Through the above improvement, the cup is more suitable for the use of long-distance pipelines.

Using different hardness of the cup assembly can be a good consideration for pig sealing, cleaning effect, passing ability, and eliminating auxiliary support. The comprehensive performance index of pigs can be optimized.

Pig selection basis

Pig selection is a multi-objective and multi-factor decision-making problem, mainly to determine the mechanical strength, wear resistance, adsorption, reactivity of the transport medium in the pipeline and the passage capacity of the pig, as follows:

Pigging target. Whether the pipe is cleaned of liquid or solid impurities, predict the amount of impurity. If more sediment impurities are expected, the pig with the discharge hole can be selected for the natural gas pipeline, and the sand can be blown up through the gas body of the discharge hole to avoid blockage.

Pipeline life cycle stage. The new pipeline is to clean residue, preliminary measurement, pressure test, drying, and trial operation. The running pipe is to clean up wax deposits and dirt, isolate the medium, and inhibit corrosion. Pipe shutdown scrap is medium removal, filling inert gas.

Determine the driving medium (oil, water, gas) characteristics of pigging.

Pipeline pig interference quantity. Consider the minimum bend radius and bend Angle of the pipe, minimum and maximum inside diameter, branch pipe connections, elevation changes along the line, and the type, position, size, etc., of valves/ bases/elbows along the line.

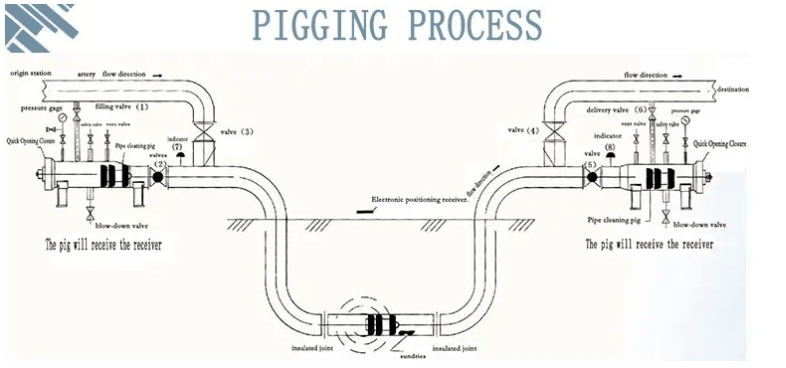

Pigging process. The range of driving pressure provided by the pipeline (maximum allowable operating pressure of the pipeline, operating pressure of the pipeline, temperature parameter change), as well as the range of possible pig speed values and the maximum distance the pig needs to run.

Dimensions of the base brush and scraper for pig installation. According to the thickness of the wax deposit in the pipeline and the range of driving force, comprehensive consideration.

Mechanical strength, wear resistance, and reactivity of pig in contact with medium in pipeline.

The development trend of cleaning pigs is to adapt to the requirements of long-distance station spacing cleaning pigs, and the requirements of pig cup configuration, cup strength, and transmitter quality are higher. Taking the Central Asia natural gas Pipeline as an example, the total length of the pipeline is 1833 km, the pipe diameter is 1067 mm, the design pressure is 9.81 MPa, the design transmission capacity is 300×108 m3/a, the distance between pigging stations is 201 km and 250 km, respectively. Two straight four-dish pigging pig with light structure and strong passing ability was selected for the first time after the pipeline was put into operation. The main technical parameters: the supporting cup and dish cup were made of polyurethane material, with Shore hardness of 85HA and 80HA, respectively. The working pressure of the pig is greater than 12 MPa, the temperature range is -30~100°C and the interference is 3%. The mass of the pig is 0.6t, the lowest pressure difference in the pipeline operation is 0.2MPa, and the longest distance of sustainable operation is greater than 300km; It can pass through the pipe whose minimum curvature radius is 3D (D is the outside diameter of the pipe) and whose maximum deformation does not exceed 25% of the pipe diameter. The tracking device can be installed, once the blockage occurs, it can find and locate the blockage position in time.

The pipeline pig is indispensable in the construction and operation of pipelines. Its main functions are as follows:

Recycle liquids from pipes to reduce waste and improve the efficiency of manufacturing and production processes

Clean the impurities in the pipeline, improve the conveying capacity of the pipeline, reduce corrosion

Isolation of different media

Pipeline pressure test

Pipeline wall corrosion detection

Pipe drying

Operating rules for gas pipeline pigging through the ball

As with any system component, 3-cup pipeline pig appliances have a long service life and a low service life guaran base. They should come in a range of sizes to suit different pipe specifications. To achieve full automation, the scraping ball should be fully detectable and ideally equipped with a specially designed pig locator or pig detection system.

Operating rules for gas pipeline pigging through the ball

Wear labor protection products correctly, conduct hazard identification and risk analysis, and implement necessary risks

Check that the pressure gauge, hand-held combustible gas alarm device, and hydrogen sulfide detector are within the effective checking period.

Use an vernier caliper to measure the ball diameter, the interference should be 3%-5% of the inner diameter of the ball tube, and carry out appearance inspection, there should be no major cracks and record.

Set monitoring points in exposed parts of natural gas pipelines.

Close the gas metering instrument from the ball pipeline to prevent excessive fluctuation of gas volume and pressure from damaging the instrument.

The service station shall cut off the external natural gas delivery and vent, and the ball receiving station shall cut off the external gas delivery valve, fully open the ball receiving cylinder valve, and open the ball cylinder blowdown valve and vent valve. Check that the receiving and baseball have enough integrity to prevent accidental hazards to people and the environment

pipeline pig

Reviews

There are no reviews yet.