Description

At present, the pig signaller used at home and abroad can basically meet the requirements of pigging line sweeping, but its maintenance, and repair are more troublesome, and most of the need for pipeline pressure relief production, economic loss is immeasurable.

Technical characteristics

Applicable pressure range: P<10Mpa

Applicable temperature range: -20℃~120℃;

Applicable pipe diameter: D≥DN100;

Applicable media: petroleum products, natural gas, and other non-corrosive fluids. The pipeline material is all kinds of metal pipelines with good welding performance and 20 steel.

The length of the pendulum needle inserted into the tube is 60 mm.

Display mode

A: Field indicating flag: manual reset

B: on-site digital display; LED digital display through the ball time and save

C: remote signal terminal (SPDT); Capacity: AC380 DC220 5A

Suitable for explosion-proof installation;

Explosion-proof mark Protection class Anticorrosive grade

EXd II BT4 IP66 WF1

Scope of application: Explosive gas mixture dangerous place: Zone 1, Zone 2

Explosive gas mixture: IIA, IIB

Temperature group: T1-T4

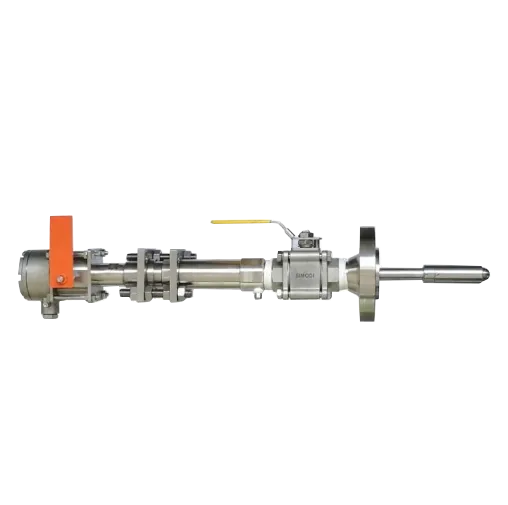

Equipment structure

Base – welded to the line (20#);

Mounting flange connecting the ball valve with the base (stainless steel);

Ball valve one is the main component of the pressure disassembly device (stainless steel);.

The main body of machinery — the main part with pressure disassembly function (stainless steel);

The pressure relief valve can be discharged twice once opened (stainless steel);

Positioning screws – limit

Connecting Ring 1 is used to connect the mechanical body to the watch head

Safety card – safety self-locking function,

Technical characteristics of clock control watch head

Clock control meter head is an explosion-proof type, and can be used reliably in petroleum, petrochemical, and other explosive mixtures formed by combustible gases belonging to Class II, Class B, Group T4, and the following places. Clock control watch head using 4 5# battery 6V power supply, to the microprocessor chip as the core, automatic memory through the ball time, low power consumption, 4 batteries can be used for 1 ~ 2 years.

Clock control head operation method

The clock control watch head is composed of four LED digital LED, two LED and three keys, four digital tubes to indicate the current time or the pig through time, two LED to indicate the ball situation, three keys to start the instrument, view the time, set the time and reset the reset function.

Preparation before the ball: press the yellow button to start the indicator: If the digital display time is accompanied by a light-emitting diode, this time is the time the ball must be cleared.

Method: Press the red key and the green key at the same time, wait until the digital tube shows “00.00”, then let go, the indicator completes the zero clearing operation. Erased the memory of the previous pass. At this time press the yellow key, the digital tube displays four bars, and you can carry out the next step

Setting time: If the instrument is not used for a long time, the time can be adjusted if there is a deviation.

Time adjustment: After pressing the start key, press the “red key” for about 3 seconds, and the digital tube “hour” display code is flashing. This indicates that hourly adjustments can be made. Press the “green key” and “yellow key” to add or subtract the number of “hours”. After the correct adjustment, press the “red key” to confirm the flashing display code of “minute” at the same time, which indicates that the time “minute” can be adjusted. Press the green key and the yellow key to add or subtract the “minutes” digit. When the adjustment is correct, press the “red key” to confirm. The digit will stop flashing and the correct time will be displayed to complete the time adjustment.

Through the ball instant display: When the pig ball is through, the ball activates the driving contact rod of the indicator, the watch head induction, and the site indicating flag started, at the same time sends out a remote switch signal, digital tube display the current time, and accompanied by flashing, 10 seconds later out. Through the time memory, the ball indicator has the clock display and the ball instant memory display function. There is a viewing process as follows:

Press the “yellow key” if the middle light tube is bright, then the digital tube displays time, Representing the time of the pigging ball through, if the digital tube shows four bars, it indicates that the pigging ball did not pass.

Note: This product is a low-power explosion-proof instrument. Instrument under normal circumstances, generally in the state of sleep, both digital tube does not show, only in the ball, view, and time adjustment when a few seconds to ten seconds of the display.

Disassembly method with pressure:

Step 1: Remove the connecting flange with a wrench and screwdriver, turn the watch head with its connecting flange 90″ clockwise, and pull it up to remove the watch head.

Step 2: Remove the positioning screws using an Allen wrench

Step 3: Rotate the core and the safety card counterclockwise with a wrench and move them upward at the same time

Step 4: Close the ball valve when the opening is moved up to the air release valve

Step 5: Slowly remove the air release valve (note: do not put the air release valve port directly to the human body), and release the residual pressure; If the air is discharged continuously, check whether the ball valve is tightly closed. If no pressure exists, perform Step 3 to completely remove the core.

Step 6: Remove the shaft pin and pendulum pin

Step 7: Remove the retainer ring · Pull out the connecting rod before replacing the 0-ring seal

pig signaller

Reviews

There are no reviews yet.