Description

Definition of pig indicator

Technical characteristics

1, The use of pressure 0-6.4MPa(64kg/cm2) the use of temperature 0-80 ℃.

2. The installed pipeline requires pipe diameter D2DN150 and the transport medium is petroleum products. Natural gas and other non-corrosive fluids. The pipeline material is all kinds of metal pipelines with good weldability with A3 steel.

3. The length of the trigger inserted into the tube is 80mm

4. When the pipeline passes through the pig in both directions, the indicator can display normally.

5. The installation height of the equipment under normal operating conditions is 340mm, such as in the valve well. The user can request an SN-TQZ elongated type (with a flexible pipe to transmit the action) within the installation height range below 1.8m. Raise the height of the display instrument for easy observation.

6, clock control indicator using electronic clock core body, a No.5 battery as a power source, trigger swing 45℃, clock stop display pig through time, can also be connected behind the display table, output electrical signal to the control room.

7, Suitable for explosion-proof installation.

8, After the sealing inspection before leaving the factory.

9, The structure ensures the conditions of pressure installation and pressure disassembly.

10. The total weight of the equipment is 4.9kg.

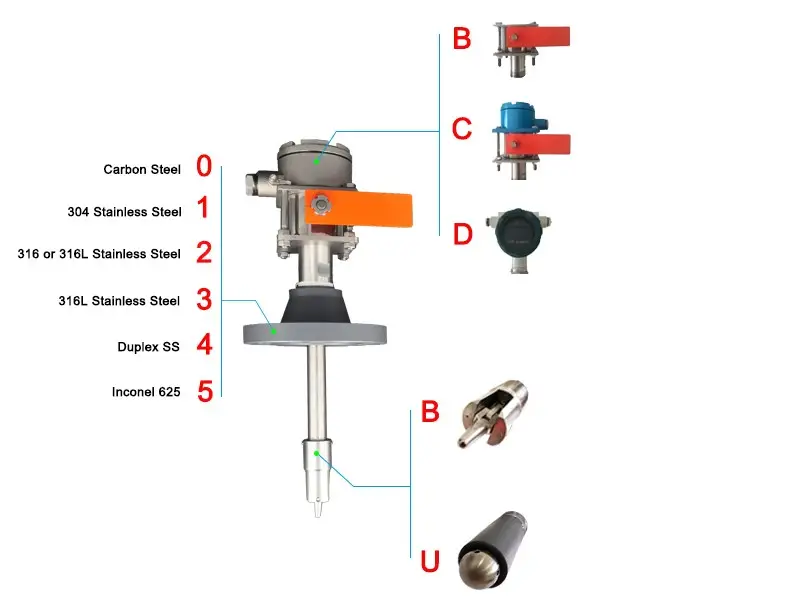

Equipment Instructions

1. The trigger is made of stainless steel and can be turned in both directions.

2. The wire plug refers to the standard 2-inch wire plug system, to meet the pressure installation of the strip melodious.

3. The base is made of A3 steel. The upper and outer sides are Zgz-external threads.

4. Type 0 sealing ring 12 x 1.9 rubber 1-3.

5. When the tappet pig pushes the trigger, it moves down.

6. Type 0 sealing ring 46 x 3.5 rubber 1-3.

7. The compression spring resets the tappet automatically.

8. Stop the washer to position the wire plug. Make sure the trigger is in place.

9. The growth stud tappet transmits the motion to the lever system.

10. The lever system converts the retractive motion into an ascending motion.

11. Fastening screw

The clock control head inner contact rod, push it, can make the clock control head stop.

Clock control head (electronic clock core type)

Adjustment of the clock control head

The clock control head is a special timer, through special design and processing, with some special performance to meet the requirements of use, the main facility in the clock control head is a standard electronic clock core after modification can trigger stop the clock control head travel time on the dial to keep the pig through, the clock control head is equipped with a No.5 battery, During replacement, unscrew the four screws on the rear cover and take the lower gland. Note: clock control head should be waterproof and dust-proof; When unloaded, the clock control head should be placed on the side, and the dial knob is not allowed to touch any object, in case of inaccurate travel time.

Various control positions behind the clock control head

1, Dock reset pull rod (only in the pull-out position, the clock to travel);

2. Place the battery knob;

3, Fastening screws;

4. Tappet support;

5, 0 rings;

6. Blockage

7. Trigger;

8, Remote electrical signal plug;

9. Timing knob.

Packing List

1. A set of mechanical main parts

2, The clock control first

3, special move hand

4. A plug

5. A copy of the instructions

6. Product qualification certificate

Indicator installation method:

1. Before installation, check that the mechanical body of the indicator and the display mechanism is flexible and reliable. Disassemble the mechanical body according to the structure and installation diagram, and weld the base and pipeline separately.

2. Welding base:

3. No-pressure installation: Clean the installation position, remove all attachments, reveal the metal color, straighten the base (welding azimuthal diagram, make the grooving direction of the upper end of the base parallel to the center line of the pipeline or the mark of the upper end of the base in the center line of the pipeline (the grooving direction of the base or the mark is consistent with the movement direction of the plate machine. Press the base to prevent displacement or deflection during welding.

4. Installation with pressure: (refer to the instructions of the opening machine.

Note: When soldering the base on the pipeline, limit the pressure P in the pipeline.

Pipeline wall thickness mm.

Additional wall thickness (negative thickness deviation, corrosion margin, etc.) is generally 1.5-2 mm.

After the mechanical body is welded and installed, the mechanical body shall be arranged according to the structure and installation diagram

After installation, the display mechanism is connected with fastening screws according to the structure and installation diagram, and the direction of the display mechanism can be adjusted for easy observation.

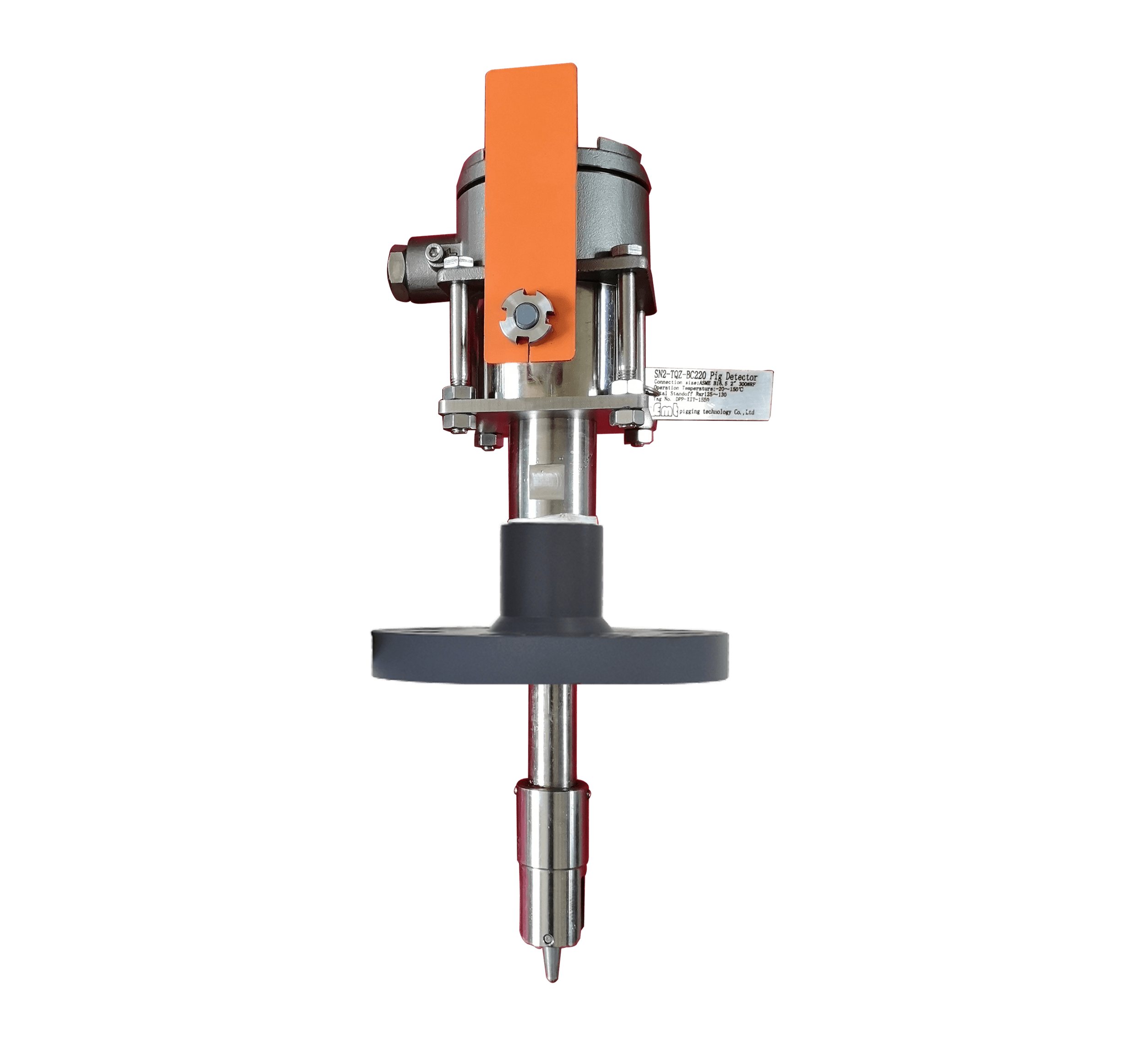

pig indicator

Reviews

There are no reviews yet.