Description

Function and use

Structure of quick opening closure

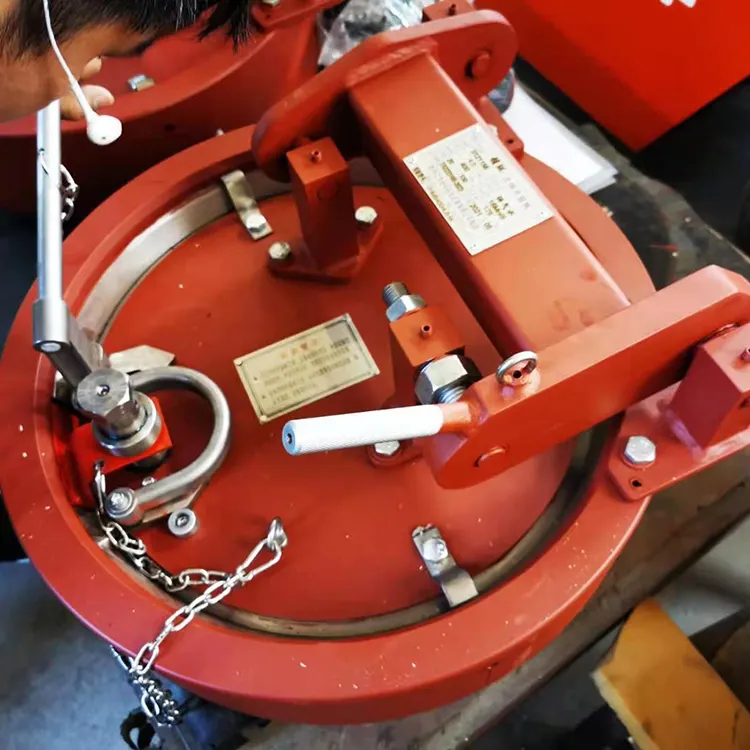

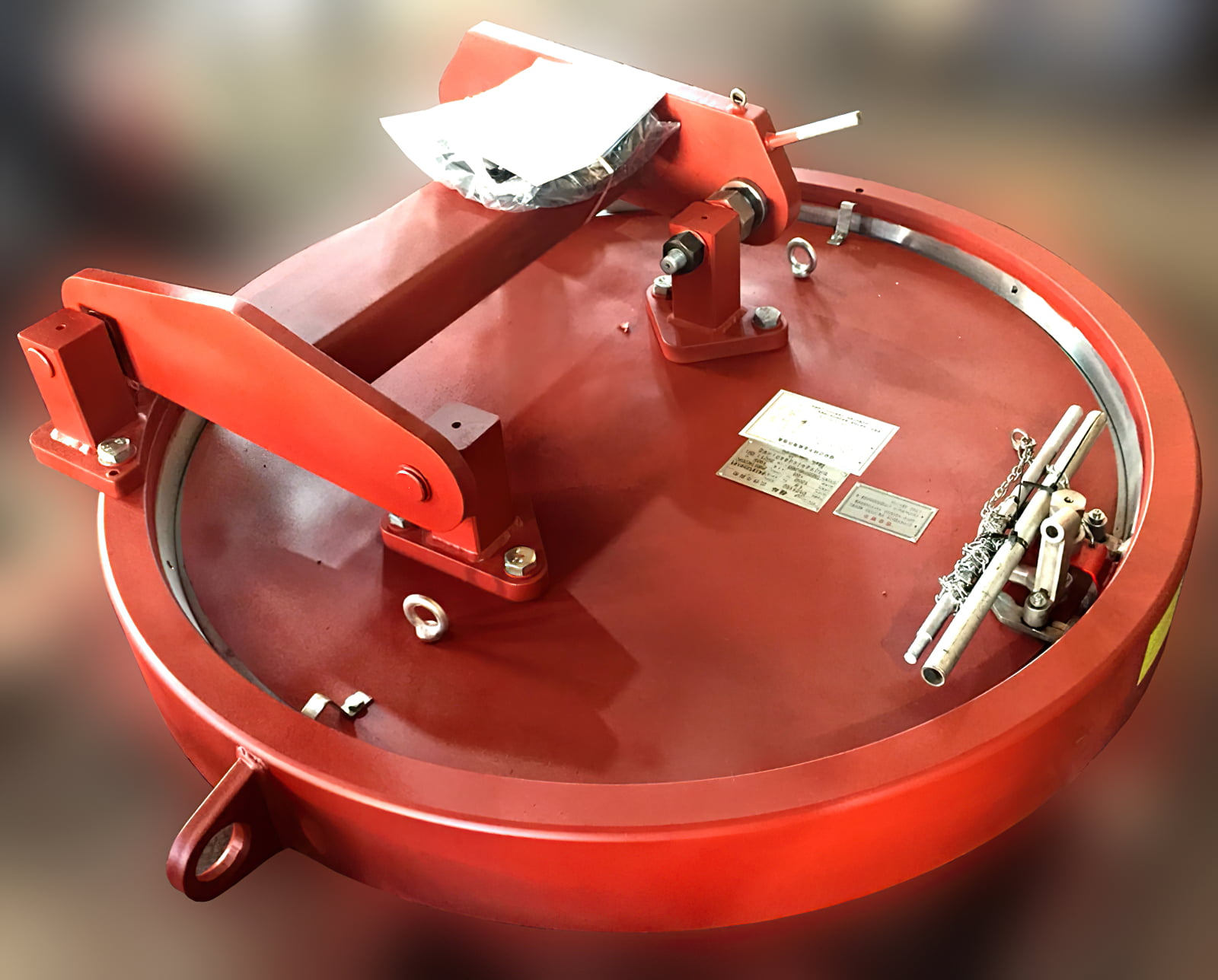

1, handle 2, safety lock valve 3, blind plate cover 4, clamp 5, type 0 sealing ring 6, blind plate seat 7, switch screw 8, safety clamp 9, the safety positioning pin 10, rotary hinged shaft 1 adjustment nut 12, pin shaft

Safety self-locking quick opening closure is divided into horizontal and vertical installation forms,

Horizontal safety self-locking quick opening closure is mainly composed of a head cover, end flange, sealing ring, locking mechanism, safety interlocking and alarm mechanism, and opening and closing mechanism; Vertical safety self-locking quick opening closure is mainly composed of head cover, end flange, sealing ring, locking mechanism, safety interlocking, and alarm mechanism, lifting mechanism and rotating mechanism; The locking mechanism is divided into two sections by a conical locking ring, and the small section is connected with the release bolt through a connecting plate as a locking block; According to user needs, vertical and horizontal can be equipped with remote transmission alarm device and mechanical key safety lock. Generally, horizontal and small and medium-sized vertical safety self-locking blind plate adopts manual operation, and large vertical blind plate adopts electric operation.

Performance index

Advanced design: Based on the lock ring type, the internal middle type head cover is adopted, with a compact structure. The design considers the influence of fatigue load, and adopts the finite element analysis and design method, integrating science, economy, and safety.

Structural self-locking: The locking structure adopts the self-locking principle. The double-phase stainless steel conical self-locking ring converts the shear force of the general locking ring structure into compressive stress, improving the state of the force.

Reliable sealing: The sealing ring is made of stainless steel and rubber, and the sealing mating surface is made of a flat push structure, reliable performance, and easy maintenance.

Multiple interlocking and double alarms: Pressure release bolt and lock block are connected as one through the connecting plate. In the case of residual pressure, when the release bolt is not removed, the lock block can not be removed as one, the lock ring can not be retracted, and the head cover can not be opened; Optional remote transmission alarm device, control room operators can easily know the opening state of the blind plate; The lifting and rotating mechanism of the large vertical quick opening closure are automatically interlocked. The operation of the first step is not in place, and the next step cannot be started. Optional mechanical key safety lock to prevent

Open efficiently and conveniently: One person does not need any special tools within 1min, only needs to rotate the handle 180″, can easily open the lock ring, horizontal blind plate one person to open the blind door, vertical blind plate no matter how large size, one person can easily complete the opening, rotation, and lifting of the blind plate within 5min, the lifting and rotation of large vertical blind door have realized automation.

Only when the whole blind plate cover is sent to the closed position, the lock ring can enter the working position, and only when the lock ring is in position, the lock block can be in position, and then the release bolt of the blind plate cover can be installed, otherwise, the pressure cannot be raised, thus forming the interlock control function.

When the internal pressure of the pressure vessel is completely released and the safety interlock device is removed, the linkage function of the quick door can be opened

If you want to open the blind plate cover, you must first unscrew the release bolt of the blind plate cover, and the unique incision of the end of the release bolt is processed when the bolt is screwed, and the inner and outer parts of the pressure vessel are connected at a certain Angle. At this time, if the internal pressure of the pressure vessel is not completely discharged, there will be leakage media overflow and sound, which will remind the operator not to open the operation. That is, only when the internal pressure of the pressure vessel is ultimately released and the release bolt does not alarm can the lock block be removed, and then the whole blind plate cover can be moved to the open position after the lock ring is shrunk.

It has a warning function synchronized with the above actions. The uniquely designed release bolt with an end notch can generate an alarm sound under the above two conditions, and the quick opening closure is equipped with a remote transmission alarm device.

Safety precautions for quick opening closure operation

Check that the indicators on the container are normal.

Check that there is no leakage in the connecting parts of the container and quick opening closure.

Necessary explosion-proof tools, fire extinguishers, fire MATS, and other facilities are ready.

Before opening the blind plate, it is necessary to open the ball drum vent valve, and in the cleaning process, open the container water injection control valve, and keep it normally open, to ensure that there is no pressure in the cylinder operation.

The operator shall stand on one side of the opening and closing mechanism, and any personnel and equipment shall not stand and be placed directly against the quick opening closure;

Do not use the safety valve to relieve pressure. Tighten the safety pin after closing the blind plate.

Check that the indicators on the container are normal;

Check that the connection parts of the container and the quick-opening blind plate do not leak. Necessary explosion-proof tools, fire extinguishers, fire blankets, and other facilities are ready;

The operation of opening and closing the blind plate is carried out by one person and supervised by other personnel; In the process of opening and closing operation, the front of the quick opening official board cannot stand.

Unscrew the pressure release bolt and bring the retracted lock to the open position.

Make sure the door is adequately supported by the sling (large doors have to lift lugs) and loosen the first item in the image above – the door shaft pin bolt and the second item – the dowel.

Now the door can be safely removed from the blind.

Operation method

The opening of the blind plate

Check that the container inlet and outlet valves are fully closed.

Open the vent valve for vent and observe until the pressure reaches zero.

When there may be FeS powder or silt in the equipment, clean water of about 10% of the equipment volume is injected into the equipment through the pressure gauge vent valve on the equipment or pipeline, and wet operation is carried out. After the wet operation, the container can be dried and qualified before being put into operation again.

Unscrew the relief bolt. If residual pressure is indicated, tighten again and wait until no residual pressure is confirmed. Unscrew the safety relief bolt assembly.

Then remove the omnidirectional handle and use the door hinge handle to rotate the door.

Blind plate closure

Check that the seal ring is intact and the installation direction is correct.

Ensure that the sealing surface and sealing groove are clean.

Grease the sealing groove, sealing surface, and lock ring sliding surface.

Gently push the door forward. When the lock ring edge touches the door shaft, push the door into the neck of the blind plate.

After confirming that the door is in place, insert the handle into the drive connection and turn 180 degrees clockwise.

quick opening closure

Reviews

There are no reviews yet.