Description

Principle of resistance corrosion probe monitoring

A resistance probe is an effective tool to study the corrosion of equipment. It can continuously monitor the corrosion status of equipment in the process of equipment operation, accurately reflect the corrosion rate and its change in each stage of equipment operation, and can be applied to a variety of different media, not affected by the dielectric conductivity, its use temperature is only limited by the material.

The working principle of the corrosion probe

In corrosive media, as a measuring element of the metal wire is corroded, the diameter of the wire decreases, the resistance increases, and the resistance change can be measured by the principle of bridge balance to convert the corrosion thinning of the metal wire. When the material of the wire used is the same as that of the equipment being measured, the corrosion rate of the wire can be used to approximately represent the corrosion rate of the equipment.

The resistance probe is used to measure the corrosion rate of the resistance probe wire if the length is unchanged, the cross-sectional area decreases evenly, and the resistance value increases to measure the resistance value of the probe wire change, so as to measure the change of the diameter of the probe wire, the metal corrosion rate. The method is to add a constant current to the probe wire, measure the voltage value at both ends of the probe wire, calculate the resistance value of the probe wire, obtain the diameter of the probe wire, and calculate the rate of metal corrosion. In order to eliminate the measuring error caused by temperature, a temperature compensation element is added to the measuring structure.

The purpose of using online corrosion monitoring technology:

Track the corrosion behavior of metal surfaces in the real environment, master the corrosion rate and corrosion condition of metal, guide the process in real-time under the existing condition, take corresponding process corrosion prevention measures, and control the corrosion rate within the required range.

After many years of measured data, calculate the actual annual corrosion rate, combined with the thickness measurement technology, calculate the remaining wall thickness of the equipment and the corrosion status of the equipment’s internal parts, to determine whether the equipment meets the needs of safe production, so as to determine the equipment maintenance cycle, for preventive maintenance

Resistance probe online corrosion monitoring system

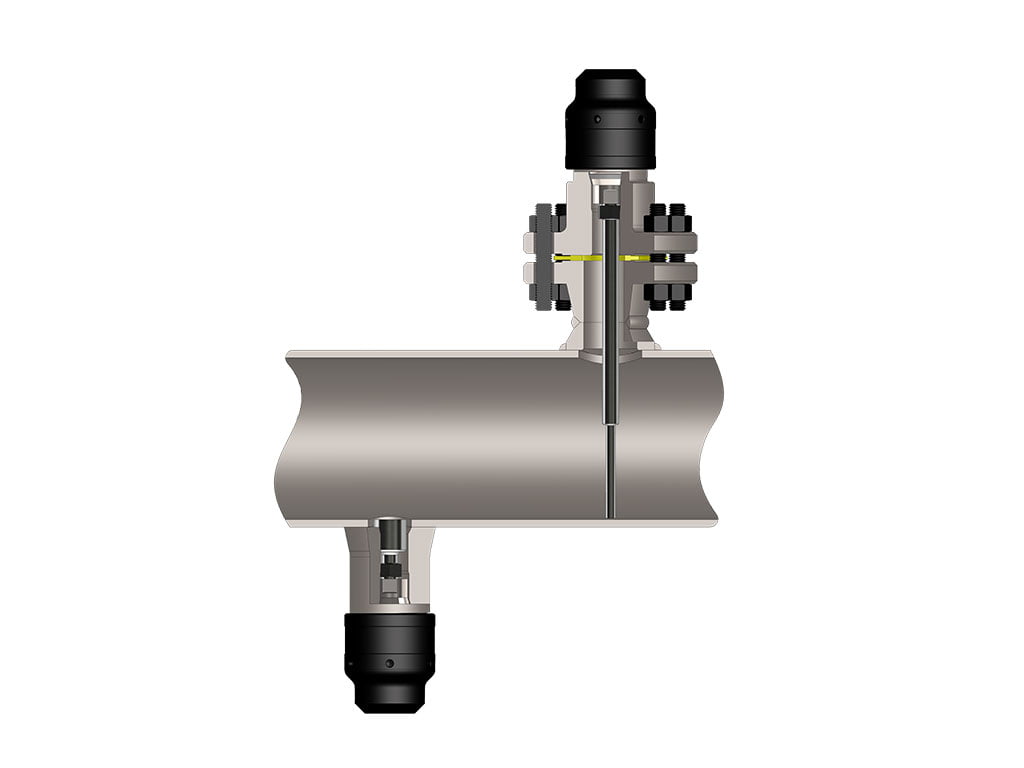

The monitoring system consists of a field corrosion data collector, corrosion resistance probe, and data process transmission system (including data conversion interface, external power supply, computer equipment, and measurement software).

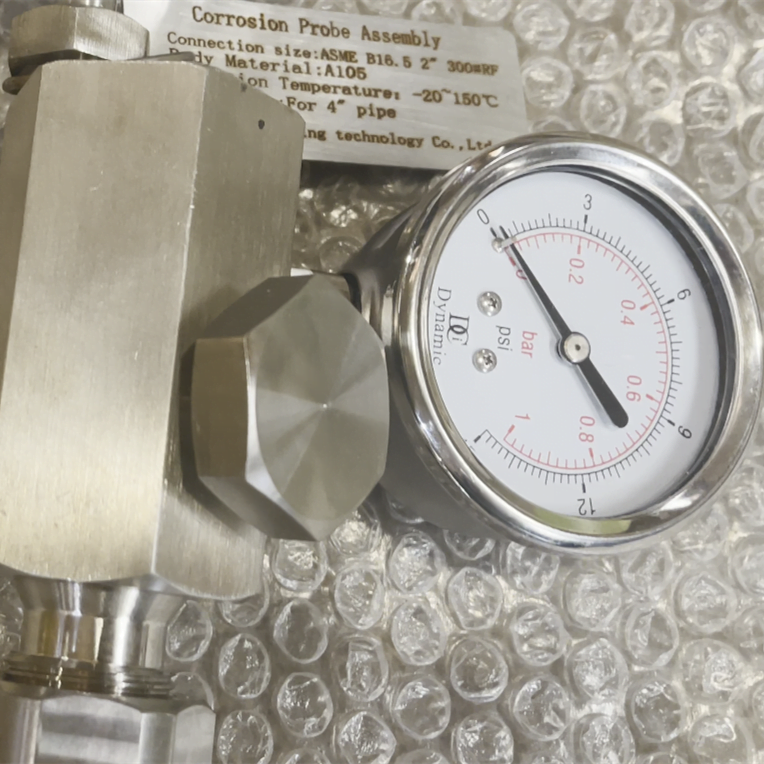

Corrosion monitoring resistance probe structure: The resistance probe measuring element (resistance probe) is a fine wire, with a diameter of 0.6mm, direct contact with the medium, and a temperature compensation element in series in the resistance probe tube, in order to eliminate the influence of temperature change on the resistance of the resistance probe wire, so as to reduce the system error. The probe is installed vertically on the process line and is of stuffing box type with a pressure detachable structure to facilitate the replacement of the probe and continuous measurement during normal production.

The corrosion data collector collects the original analog signal of current and voltage related to corrosion speed, converts it into a digital signal after amplification, and sends it to the monitoring computer. The software is used to process the obtained data and get the required resistance value. The online monitoring system of resistance probe corrosion calculates the corrosion depth and corrosion rate of the measured component by measuring the relative signals of the resistance probe and the temperature compensation element and obtaining the resistance ratio.

Conclusion

When measuring medium is gaseous or no active metal ions in solution, the resistance probe corrosion real-time online monitor can track the corrosion behavior of metal surfaces in the real environment, master the corrosion rate and corrosion condition, so as to timely take corresponding corrosion prevention measures to control the corrosion rate within the required range, but the actual annual corrosion rate cannot be obtained.

Due to electrical measurement, when the medium is a solution and there are metal ions that are more active than the metal to be measured, the electroplating reaction will occur on the probe wire and the probe will lose its function. Therefore, this method can only be used in the environment without active metal ions in the solution or to improve the electric process and time.

The resistance probe corrosion real-time online monitoring system has stability in the stable simulation system. Still, in the measurement system, there will be a significant jump in the data, the cause of which and the impact on the corrosion measurement results need to be further analyzed.

In the future, it should be solved how to smoothly connect the two measurement curves to reflect the true value of the annual corrosion rate after replacing the probe wire, because the measurement zero is reset.

Corrosion products under the action of a corrosive medium, have a certain conductivity, At this time the probe continued corrosion caused by the increase of the resistance value, and the conductivity of the corrosion products caused by the probe resistance value decreased to supplement, so that the measured data can not reflect the actual corrosion condition, should be as a topic for in-depth study.

Reviews

There are no reviews yet.