Description

Definition of corrosion coupon

Purpose

To monitor or evaluate the corrosion status of the cooling water system. Generally, the pre-treated and weighed metal test pieces are placed into the test system for a period of time (such as 30~90 days), then taken out to observe the corrosion condition, cleaned, and weighed to determine the weight loss degree of metal corrosion (mil/year,1mpy=0.0254mm/a), corrosion type and pitting depth, etc. The data of metal hanging pieces are not only affected by the corrosive medium, but also related to the surface treatment of hanging pieces, the position of placement, the length of exposure time, and the metallurgical method of sample pieces.

Corrosion mounting is a simple and effective tool for quantitatively evaluating system corrosion rate. It also provides a visual indication of the types of corrosion that may occur in the monitored system.

Corrosion coupons are:

A piece of metal whose shape, size, and surface area have been determined

A metal that is chemically similar to a processing device

With a uniform surface finish

It has a distinct serial number

Exposed to the same corrosive medium as the process equipment

Fixed exposure time

Gives a visual indication of the type of corrosion

Indicated corrosion rate

Each etched piece is engraved with its unique serial number, and we provide written proof of each order, including serial number, material, weight, and size. Each piece is accurate to four decimal places in weight and is individually packaged in a moisture-proof and gas-phase corrosion-resistant envelope to ensure a one-year warranty.

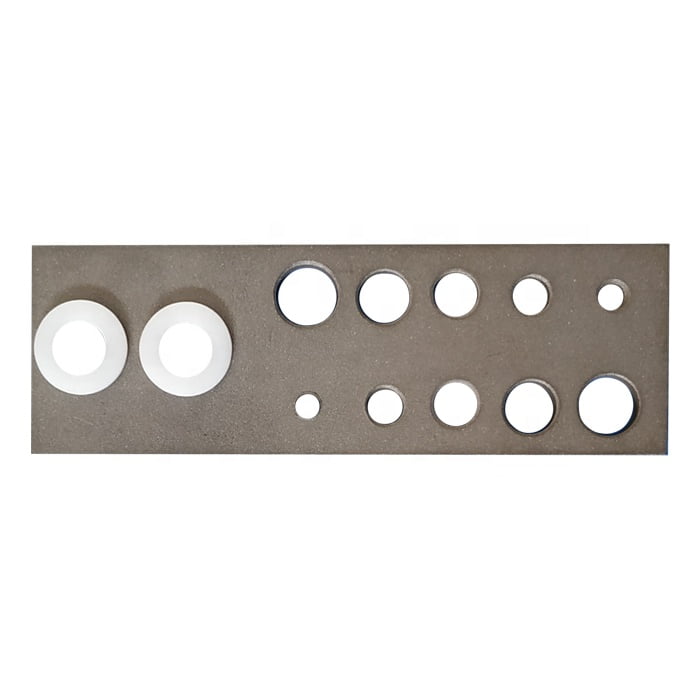

Standard hanging piece

Standard hanging coupons are sanded and insulated for installation. The mounting hardware is provided with the mounting bracket. The hanging piece is allowed to be polished, polished, or welded.

The material and size of the hanging pieces can be customized or supplied by the customer to match the existing system.

Strip hanging piece — 1/2 “width

Used for low-pressure mounting equipment or standard 3/4″ wide hanging pieces cannot pass through narrow channels. The size is 3″ x 1/2″ x 1/16″(76.2mm x 12.7 mm x 1.6 mm) with two mounting holes. The exposed area of the hanging piece is 2.65in2 (1,709mm2).

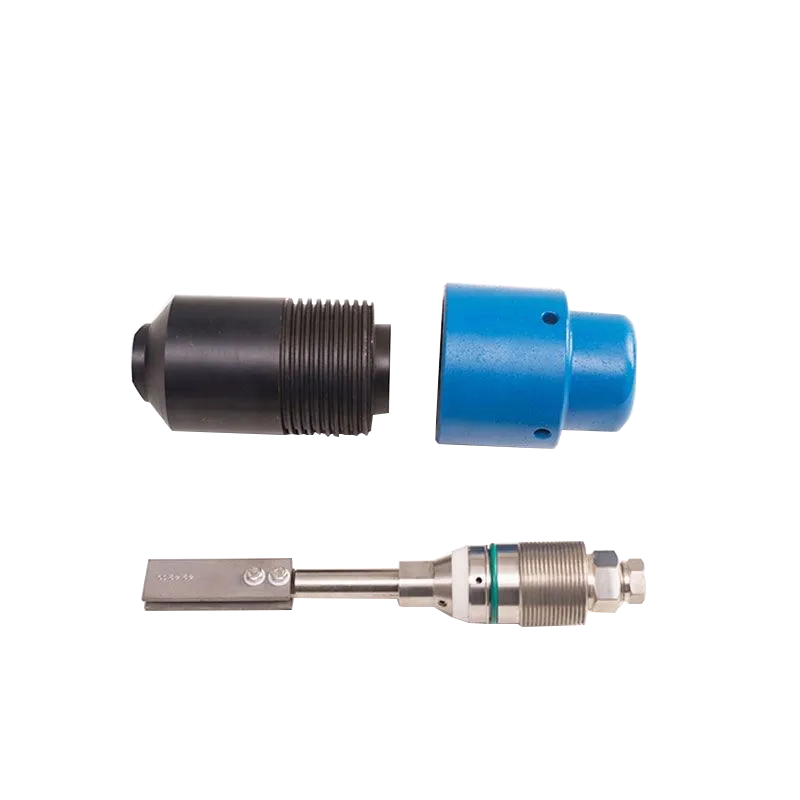

Cylindrical hanging piece

The pencil-shaped mounting bracket is insulated with an NPT plug-type mounting bracket by screws. Standard cylindrical hangers are O%” x 4″ (O6.3mm x 101.6mm) with milled flat engraved serial numbers. The threaded end of the mounting coupon is screwed into the insulator and the transverse notch at the other end accepts a flat-head screwdriver. The exposed area of the hanging piece is 3.27in2 (2.109mm2)

Special-purpose hanging pieces and supports

Applied stress-corrosion cracking environment

Residual stress – embrittlement environment

Scale mount – An environment in which scaling may occur

Storage and use method:

1. The standard corrosion test piece (corrosion measuring hanging piece) in distilled water with degreasing scrub again, and then rinse with distilled water for 15 seconds;

2. The standard corrosion test sheet (corrosion test hanging sheet) in chemical pure anhydrous ethanol (50ml/ every 10 pieces) with degreasing scrub twice;

3. The standard corrosion test piece (corrosion measuring hanging piece) is placed on the drying filter paper and dried by cold air;

4. The standard corrosion test piece (corrosion measuring hanging) is wrapped in filter paper and placed in the dryer. After 24 hours, it is weighed and ready for use.

5, The original package test piece is placed in a place without corrosive gas, moisture-proof storage;

6. The standard corrosion test piece (corrosion measuring hanging piece) that has been opened and not used up shall still be placed on rust-proof paper and placed in the dryer.

Treatment of new hanging pieces (standard hanging pieces in sealed packaging) :

1. Dip the new hanging piece into anhydrous ethanol and scrub it twice with absorbent cotton;

2. Then soak in clean anhydrous ethanol for a while;

3. Place on clean filter paper and dry with cold air;

4. Wrap it with filter paper, put it in the dryer, and weigh it 24 hours later for use (weighing accurately 0.1g). Treatment of hanging piece after use:

Treatment of hanging piece after use:

1. Carefully take out the hanging piece after use, and observe and record the surface condition before processing;

2. For those whose corrosion deposition is not obvious, wipe them with a drawing eraser to make them show their metal color, then dip them in anhydrous ethanol and scrub them with absorbent cotton twice, then soak them in clean anhydrous ethanol for a while, take them out, put them on clean filter paper, dry them in cold air, wrap them in filter paper, put them in the dryer, weigh them 24 hours later (weighing accurate to 0.1mg), and get weight loss. Calculation of corrosion rate;

3. For the hanging pieces with more corrosive deposits, the corrosion products should be removed by the chemical cleaning method first. After chemical cleaning, the hanging pieces should be immediately immersed in 5N sodium hydroxide solution for passivation for a while, and then immersed in clean anhydrous ethanol, dried with filter paper, and wiped with a drawing eraser to reveal the metal color

Corrosion coupon

Reviews

There are no reviews yet.