Description

Corrosion coupon. A corrosion coupon is a piece of metal with a measured area placed in the system, and its material is generally similar to or the same as the equipment or pipe. The weight before and after the corrosion coupon test is measured, and then according to the weight loss and placement time of the corrosion coupon in the medium, the actual situation of fluid corrosion on the material is calculated, mainly the rate of corrosion loss or weight gain. This method is the most widely used, direct, and effective method in oilfield corrosion monitoring and laboratory evaluation of material corrosion properties. This monitoring method can be applied to a variety of industrial environments, whether water medium, oil medium, or gas environment can be used, but in high-pressure systems, some auxiliary tools are needed;

Corrosion coupon is one of the most widely used and effective corrosion monitoring methods in petroleum production. With the continuous improvement of corrosion management requirements, in addition to the average corrosion rate analysis of corrosion coupons, if the data attributes of corrosion coupons are to be explored more comprehensively, it is also necessary to conduct a comprehensive and multi-dimensional analysis of its installation status, exposure environment, disassembled morphology, adhesion composition, corrosion microstructure, etc., so as to better reflect the corrosion trend and possible risks.

Precautions for installing corrosion hanging plates

Type of corrosion coupon.

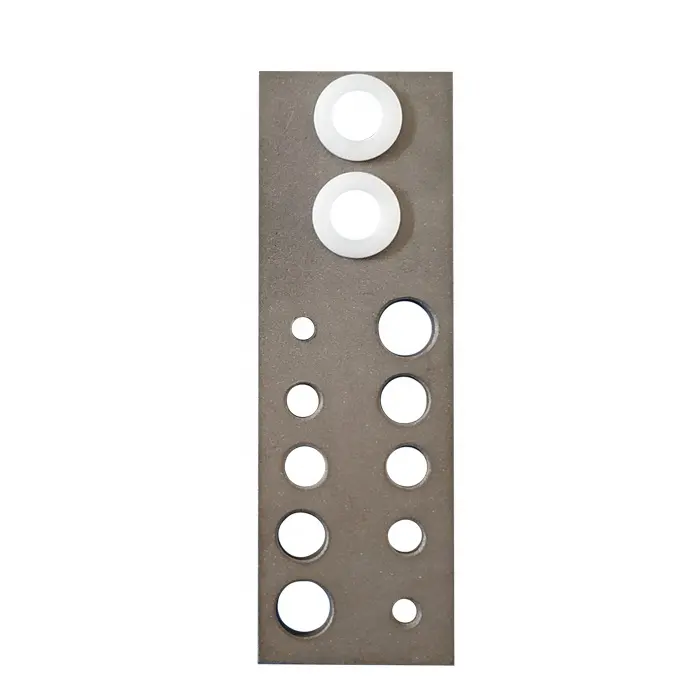

The size and shape of the corrosion coupon are determined according to the type of corrosion coupon support, pipeline size, inlet direction, and monitoring purpose. At present, there are three kinds of corrosion coupons commonly used in oil and gas fields, namely, ladder-type strip corrosion coupons, porous corrosion coupons, and disk corrosion coupons.

Material requirement

The material selection of the corrosion coupon usually matches the material of the system on which it is located.

Installation position

In order to obtain reliable information from hangers or other corrosion monitoring devices, hangers should be installed where corrosion is occurring or is most likely to occur, generally at 12 o ‘clock in the pipeline direction. Other special positions that are prone to corrosion are also recommended to arrange hanging monitoring, such as dead water areas; High-velocity zone and collision zones; low-lying positions in a pipeline; and Liquid/gas conversion areas.

Mounting mode

3 “strip corrosion coupon pair

6″strip corrosion coupon pair

A circular corrosion coupon

Monitoring Time

The determination of monitoring time is very important when analyzing the data of corrosion hangers. For example, when evaluating the effect of corrosion inhibitors, short-term monitoring (15-45 days) is often used to obtain the corrosion rate of the system quickly. However, for some more complex and serious corrosion conditions, such as microbial corrosion and scaling, longer monitoring time (60-90 days) is needed to better complete.

Precautions for removing corrosion hanging plates

Scaling and corrosion products: Scaling and corrosion products on the corrosion hanging sheet cannot be wiped off directly on site. They should be kept sealed together with the hanging sheet and sent back to the laboratory for analysis and treatment.

Preservation and transportation of corrosion coupons

After the corrosion coupon is removed, it can be packed in a ziplocked bag or a moisture-proof anti-corrosion envelope to avoid the corrosion coupon being oxidized, which will affect the analysis of results; At the same time, make labels and send them to the laboratory for analysis.

Matters needing attention

During operation, if leakage occurs due to inadequate installation, protective measures must be taken to avoid damage to people and equipment by leakage. If the leakage is flammable and explosive, fire prevention and explosion-proof measures should be taken.

Explosion-proof tools must be used

The operator must ensure that the operating temperature and pressure do not exceed the limit value, otherwise, it will lead to leakage and associated danger.

The operator must send a signal to the control room personnel before each operation, and report to the control room personnel when oil and gas leaks.

Points for attention in hanging test

According to the experimental requirements, strictly carry out the hanging treatment.

Record the status of each link of the corrosion coupon in detail.

Precautions of electronic balance, correct use of electronic balance.

Do not touch the hung test piece with your hands or other dirt.

Place the original packaged test piece in a place without corrosive gas and store it moisture-proof;

For the standard corrosion test piece (corrosion measuring corrosion coupon) that has been opened and not used up, it is still placed in the rust-proof paper and placed in the dryer.

Corrosion coupon

Reviews

There are no reviews yet.