Description

Operating procedures for corrosion coupon

Prepare

Protective equipment: positive pressure air breathing apparatus, protective glasses, protective gloves, portable hydrogen sulfide detector.

Tools: 29mm explosion-proof plate hand, 1″ mechanical hand, 1″ /.” mechanical hand, 12″ adjustable wrench, 60-90mm explosion-proof hook head plate hand, 105mm explosion-proof plate hand, plastic hammer, takeout and release device, hand pump, safety air storage tank (lye), connecting hose, cleaning tools, 8 mm and 5mm flat mouth driver, operation record card.

Operational inspection

1. Check the installation of the pipeline under pressure

2. Make sure you have enough room for the retractor.

3. Confirm line pressure and estimate pressure fluctuation range.

4. Confirm that the hydraulic fixture is in good condition.

5. Make sure the safety cover is fully tightened.

6. Check each time by unscrewing the locking pin, one at a time.

7. Check the 0 rings of the locking pin for cuts and wear, and replace them if necessary.

8. Check and clean fittings and 0 ring surfaces.

9. Check the condition of the hanging piece and the hanging piece holder. If it has oil or other compounds on it, remove it with acetone

The installation procedure of pressure pipeline corrosion hanging piece

1. Wear safety glasses when using the dispenser.

2. Open the extractor facing up and connect the extractor to the pump with a hose. Push the pump into the “mount” position and apply pressure until the rod sticks out.

3. Screw the plug-in and the hanging piece on the connecting rod, push the pump to the “retrieve” position, and relieve pressure until all the coupon return to the retrieving device.

4. Remove the safety cap and install the maintenance valve on the fixture

5. Lift the retrieval device and put it on the maintenance valve. Screw the impact nut on the maintenance valve and tighten it.

6. Pump to the “Install” position.

7. Balance the pressure on both sides of the maintenance valve by:

8. Standard maintenance valve: Slowly open the bypass valve, and the pressure in the retrieval device will rise to the same as the pressure in the pipe (can be read on the pressure gauge).

9. Double ball seal maintenance valve: Slowly open the bypass valve of the upper ball valve, and then open the upper ball valve. Slowly open the lower ball valve bypass valve. The pressure inside the retrieval device will rise to the same level as the line pressure.

If the pressure on both sides is not balanced, there is most likely dirt in the bypass valve, which makes it difficult to keep the valve open. When the line pressure is too high (above 50 bar), it may be necessary to flatten the line with a pump.

To balance the pressure with the pump, use the following steps:

10. Pump to the “retrieve” position and relieve pressure until the hanging piece is completely inside the retrieving device.

11. Install the quick back pressure connection assembly on the relief valve to ensure that the relief valve is open;

12. Keep the pump in the “fetch” position, boost the pressure until the pressure in the fetching device equals or exceeds the line pressure, and then close the pressure relief valve;

13. Remove the hose from the pressure relief valve and open it back to its original position.

14. Check the leakage between the retrieval device and the maintenance valve by observing the pressure of the pipeline in the extractor. If there is no leak, open the maintenance valve.

15. Push the pump to the “install” position and increase the pressure until the solid cock and the hanging piece enter the position they should be in the device. The number of pressures depends on line pressure and retrieval device size. The pump accompanying the retrieval device is a two-stage pump, with about 30 bar from the first stage to the second stage, so if the pressure is below 30 bar, about 30 to 60 times of pressure. If the pressure is higher than 30 bar, press 400 to 600 times.

15. Carefully open the pressure relief valve of the extractor to reduce the pressure in the maintenance valve. Connect the relief valve with a hose with a safety relief tank to hold the outgoing gas or fluid. Drain as much liquid as possible from the retrieval device before removing the hose. There must be security measures.

Matters needing attention

Close the pressure relief valve and wait 1 to 2 minutes. Then open the pressure relief valve again and check whether there is pressure in the retrieve valve. If there is pressure, it means that the solid plug in the fixture is not sealed well. If this happens, pump the pressure in the extractor to at least 100 bar above the line pressure, then loosen the locking pin and tighten it again to check for further leaks. If so, the solid plug must be removed for inspection or replacement of the main packing.

Clean the bottom of the plug-in, and the hole of the plug-in. Remove all dirt and water.

Check and lubricate the threads of each connecting device.

Install the full cover and tighten it with a 105mm wrench to relieve the pressure on the locking pin.

1, in the operation, due to the installation is not in place leakage, there must take protective measures to avoid the leakage of people and equipment damage. If the leakage is flammable and explosive, fire prevention and explosion-proof measures should be taken.

2. Explosion-proof tools must be used

3. The operator must ensure that the operating temperature and pressure do not exceed the limit value, otherwise it will lead to leakage and associated danger.

4. The operator must send a signal to the control room personnel before each operation, and report to the control room personnel when oil and gas leaks.

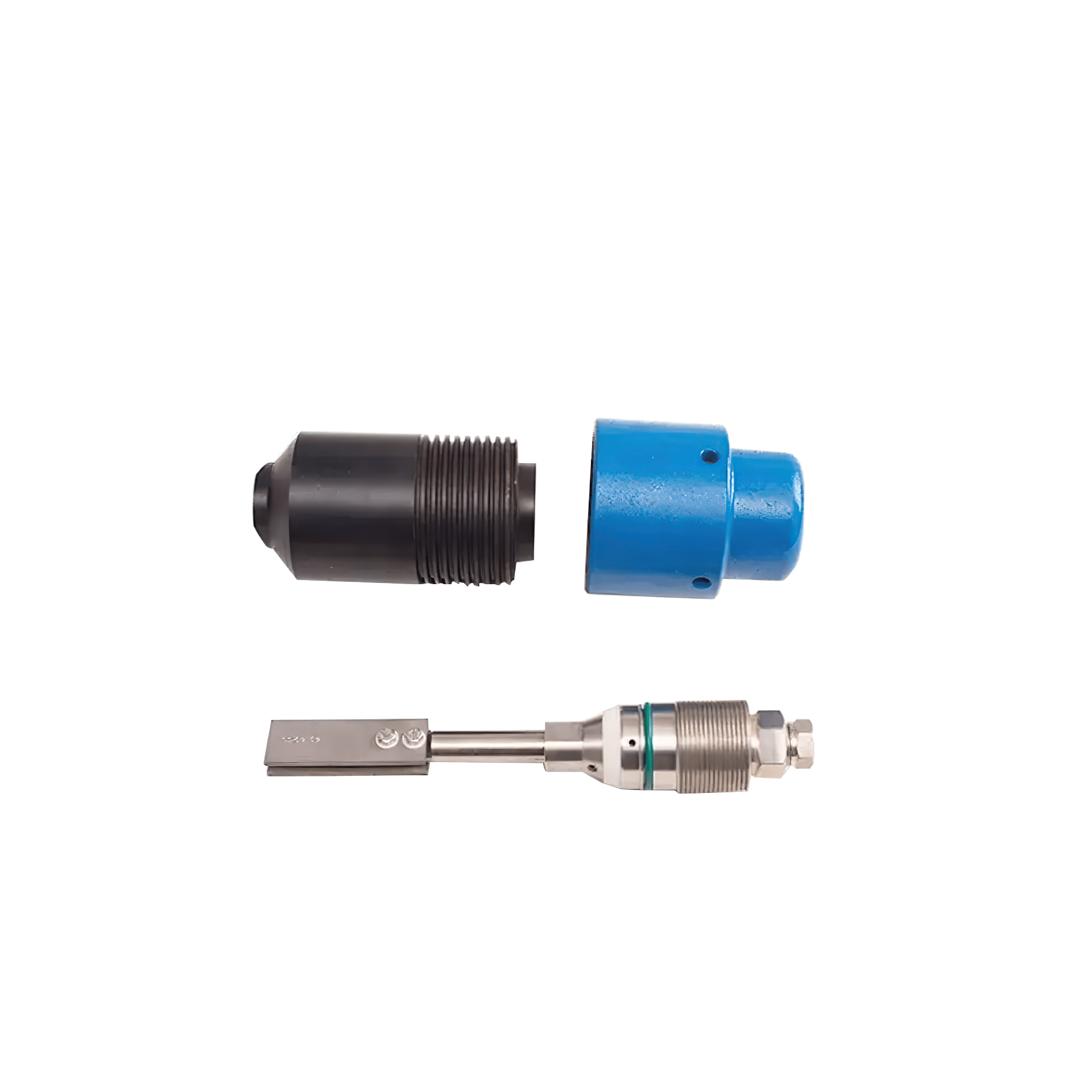

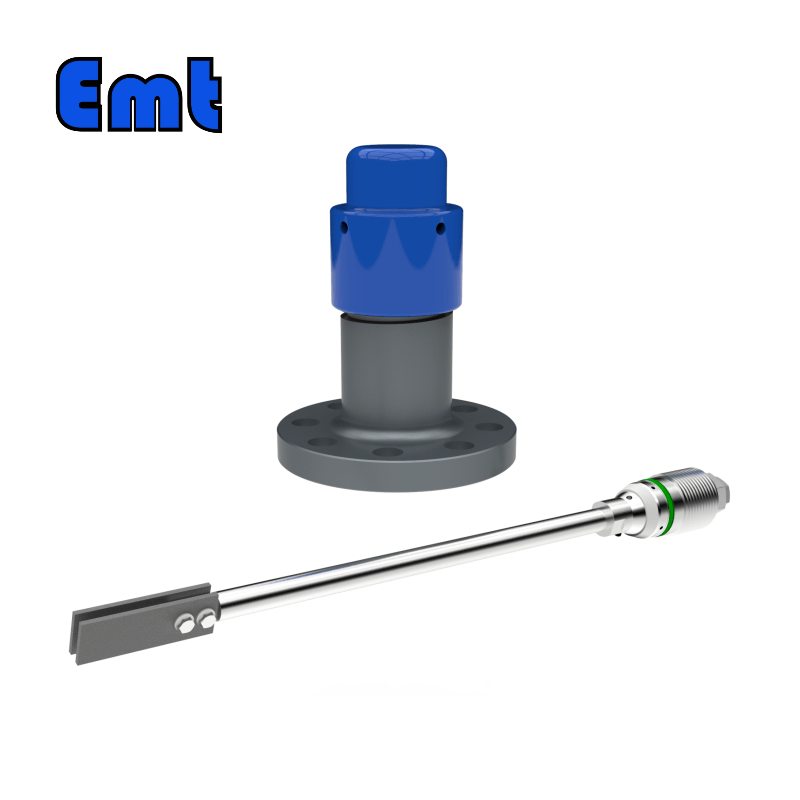

corrosion coupon

Reviews

There are no reviews yet.