Description

Advantages

With safety self-locking function (blind plate self-locking, shock-proof, anti-loosening, open can be secondary pressure relief) not only prevents the blind plate in the process of locking but also prevents the dangerous situation of opening the blind plate with pressure.

There is no relative rotation between the sealing ring and the sealing surface, and the sealing ring is not easy to be damaged, thus better protecting the sealing system.

The external lock ring will be the old blind plate buckle type into three flap type, so as to realize the locking action at the same time, uniform force, reduce the length of the opening screw, so that the switch becomes more flexible and reliable.

At the same time, the force area of the biting teeth is increased (the occlusion area of the spiral buckle blind plate is nearly 50%, and the occlusion area of the lock ring blind plate is more than 90%). It is more suitable for high-pressure and large-diameter natural gas pipelines. The main bearing parts of the blind plate are made of 20# or 16Mn1II forged steel, and the main bearing parts have no welding parts.

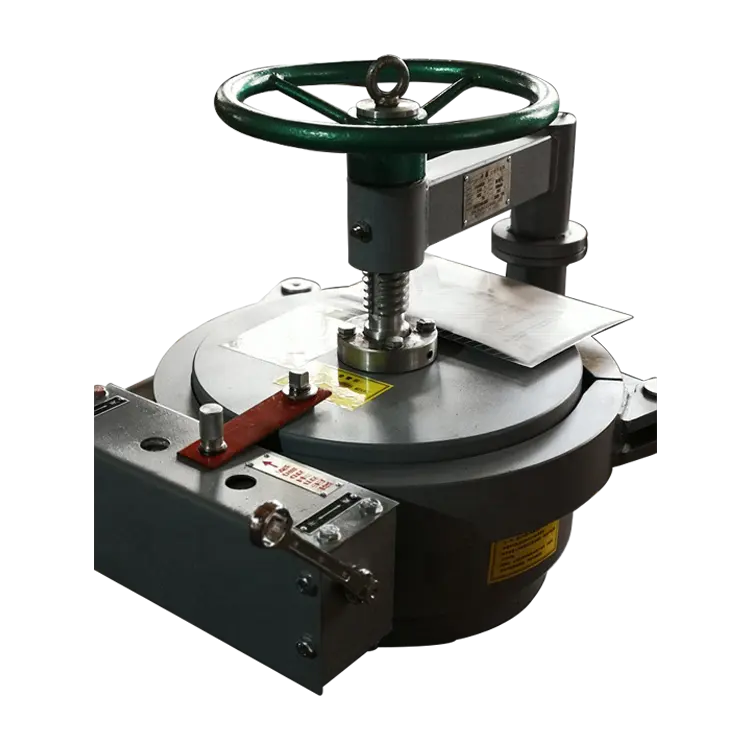

(Clamp type quick opening blind block composition)

Installation method of Quick opening closure with three clamps

1, horizontal installation, facing the blind plate cover (oval standard head ), the door shaft on the left side, and the lead screw above the horizontal. First, unscrew the exhaust bolt and remove the exhaust bent plate.

Opening and closing method of Quick opening closure with three-flap clamp:

Open the vent valve and exhaust valve of the receiving and receiving device of the pipeline installed on the blind plate to reduce the pressure in the container to zero. Unscrew the exhaust bolt and remove the exhaust bend plate.

(2) Rotate the lead screw with a wrench, so that the inner diameter of the three-valve locking ring gradually increases, and stop rotating the lead screw when the inner diameter of the locking ring is larger than the outer diameter of the blind plate cover. At this time, the locking ring is separated from the blind plate seat and cover.

(3) Pull the handle to the left to open the blind plate.

Closing process:

Apply anti-rust grease (glycerin) after thoroughly removing dirt in the sealing surface, sealing groove, and upper and lower pressure ring.

Close the blind plate and push it tight.

Use a wrench and turn the lead screw counterclockwise to compact the blind plate cover (standard head.

Insert the hole above the exhaust elbow and the positioning pin, and tighten the exhaust bolt (do not lose the sealing ring).

Blind plate cover height adjustment method:

In the process of opening and closing the blind plate, if the blind plate cover (standard head) is found to be inconsistent with the outer circle of the sealing surface of the blind plate seat, it is necessary to adjust the blind plate cover and loosen the tightening bolt; Rotate adjusting nut; Make the blind plate cover concentric with the blind plate seat (align the outer circle) and tighten the locking bolt. Make the blind plate seat and cover parallel. The seal is in good condition.

Safe operation and maintenance

The person who uses the blind plate must understand the structure and operation procedures of the blind plate.

Before opening the blind plate cover, the empty valve must be opened, and the blind plate can be opened only when the pressure inside the receiving (serving) ball barrel is reduced to zero.

When the pressure is put into the ball, the relaxation plate must be installed before it can be pressed and put into use.

After the receiver and the ball cartridge are put into use, it is not allowed to knock and collide with the main pressure parts.

The blind plate transmission mechanism and screw locking device must be often coated with oil to prevent rust. The appearance must always be intact and polished.

Regular inspection of the main bearing parts of the blind plate (such as the blind plate cover and the outer surface of the cylinder). If serious corrosion or cracks are found, the cause should be found in time and properly handled.

After each use, the sealing rubber ring and sealing groove should be cleaned, inspected, and smeared with yellow glycerin to prevent non-sealing during use.

quick opening closure

Reviews

There are no reviews yet.