Description

Introduction to the cup brush Pig

Definition

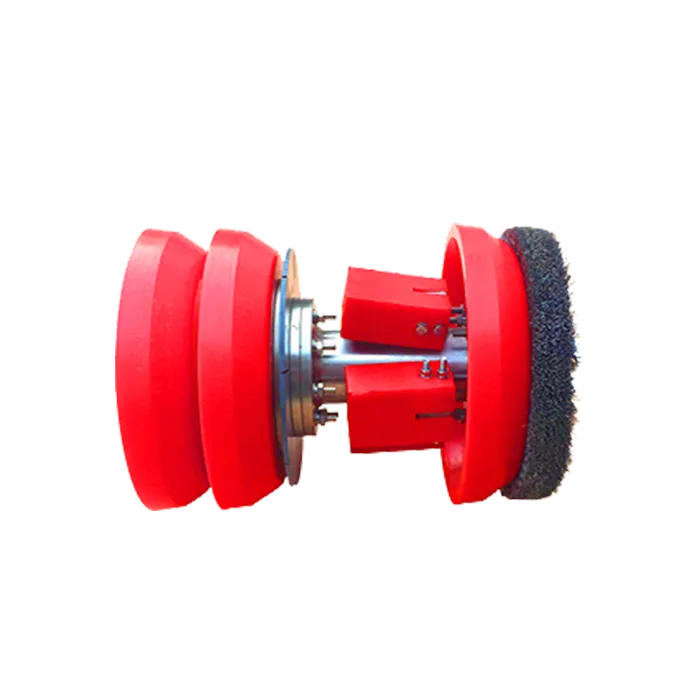

Composition

It is composed of a basal skeleton, fixed flange, 3~4 poly hydrogen ester cup, electronic positioning transmitter, bolt, nut, and other standard parts. Sbasel frame, fixed flange, 3~4 polyurethane cup electronic positioning transmitter, bolts, nuts, etc

Technical performance introduction

Through the optimized design of the structure and size of the brush pig, the latest type of brush pig is composed of four cups, which will not cause a pressure relief phenomenon when passing through the base on the line. Meanwhile, the ability to push dirt off the brush pig is greatly improved, so the passing ability and scaling ability of the brush pig are greatly improved. , mainly made the following two aspects of improvement: First, through the use of a new material, to improve the wear resistance of the cup. Secondly, the structure of the cup is changed, the traditional dish-shaped cup is changed to a double-edged cup, which increases the contact area between the cup and the inner wall of the pipe by 30%. Through the above improvement, the cup is more suitable for the use of long-distance pipelines. The cup adopts the form of a double-flanged structure, and the wear capacity of the cup is increased by 30% on the basis of not increasing the interference quantity of the cup. The cup of the pig has enough flanged edge, thickness, and interference quantity to fully ensure that it will not be deformed due to its self-weight in the pipeline, and effectively avoid the negative impact of other auxiliary machinery on the pig’s passing ability and cleaning effect. Using different hardness of the cup assembly can be a good consideration for pig sealing, cleaning effect, passing ability, and eliminating auxiliary support. The comprehensive performance index of pigs can be optimized. The cup is made of polyurethane by molding. The surface should ensure luster, and no bubbles, and cracks inside. The interference range of the cup relative to the inner wall of the pipe: is 4-7%.

Introduction to Pig Electronic Positioning Transmitter Performance

The transmitter is mainly composed of a transmitting coil, electronic circuit, and power supply. (Connected to the end of the pig, the pig constantly emits pulse signals during operation, and implements monitoring and accurate positioning of the pig with a ground positioning instrument) transmitter coil, electronic circuit, and power supply.

The main functions of a pig

Cleaning impurities in the pipeline, improving pipeline transportation efficiency, reducing corrosion, isolating different media, pipeline pressure tests, and pipeline corrosion detection.

Classification of pig

Classification of pigs commonly used in long-distance oil and gas pipelines, according to their application in the pipeline, can be divided into pig for line sweeping, pig for isolation, pig for replacement, and pig for detection.

According to its form, it can be divided into: rubber ball pig straight pig; Butterfly pig; Foam pig. The pig ball is made of oil-resistant rubber, with solid, hollow aeration, and hollow water injection in three forms. The hollow water injection type pig ball has a wall thickness of 30~50mm. There is a water injection vent hole on the ball that can be sealed. The water injection hole has a pressurized check valve, which is used to exhaust and control the water injected into the ball to adjust the interference of the inner diameter of the pig ball diameter. In order to ensure that the pigging ball is sealed to the pipe’s inner wall, the pigging ball should have a certain interference amount (generally 2%~5%). When used, the pigging ball is filled with water, so that the ball becomes an elastic entity, with a certain capacity of top extrusion in the tube. When the pipe temperature is lower than 0℃, the ball should be filled with low freezing point liquid (such as methanol) to prevent freezing. Because the pigging ball can be rotated in any direction in the tube, through the elbow, deformation parts of the performance are better, mainly used to remove the liquid in the pipe, separate the medium, and remove block objects, and the wax effect is poor.

The cup pig consists of a rigid skeleton and two or more front and back sections of the cup. While running in the tube, it maintains a fixed orientation, so it can carry a variety of testing instruments and devices.

The section of the pig cup can be divided into the main body and lip. The main body supports the weight and shape of the pig, and the lip plays a sealing role. The diameter of the main part can be slightly less than the inner diameter of the pipe, and the interference of the lip on the inner diameter of the pipe is 2~5%.

The shape of the cup has three kinds: plane, cone, and sphere. Its lip has an automatic sealing effect, that is, under the action of the pressure difference before and after the pig, it can be tightened around. This effect can maintain a certain sealing effect even after the lip is worn and the interference becomes smaller. Therefore, compared with the pigging ball, the sealing of the leather cup in operation is more reliable and the service life is longer.

brush pig

Reviews

There are no reviews yet.