Description

The definition of bare foam pig

The function of bare foam pig

“Bare foam pig” is mainly used for pipeline cleaning (water, gas, oil, chemical reagents, and other media).

1. Natural gas pipelines in operation: corrosive substances such as water, light oil, methane hydrate, iron oxide, carbide dust, carbon disulfide, and hydrosulfuric acid can be removed inside the pipelines to reduce the corrosion damage caused by corrosive substances to the inner wall of the pipelines; Re-define the pipeline direction; Detection of pipeline deformation; Check the integrity rate of valves along the line; Reduce working back pressure;

2. Crude oil pipelines in operation: pigging before testing in pipelines, and pigging of oil pipelines in low flow intermittently; Remove the condensate, wax, and scale inside the pipeline to reduce the oil back pressure, reduce the friction, and reduce the oil temperature;

3. Water injection pipeline: can be used to remove scale, sediment, etc;

4. Before the pipeline is put into operation, the pigging line is swept to remove the residue in the pipeline so that the pipeline is unimpeded;

5. Oil and gas pipelines for regular wax scraping treatment, to ensure that the pipeline has the maximum transmission capacity;

6. Used for experimental ball-passing when the internal condition of the pipe is unknown;

7. According to the customer’s requirements, we can provide a series of foam pigs with small diameter intervals for the pigging operation of thick and hard-scale layer pipelines.

The foam pig used on the pipe is commonly known as the foam ball, which is a kind of plastic foam.

According to the raw materials used in foaming, polyether foaming (sponge), polyester foaming, tetrahydrofuran foaming, etc., the commonly used pipeline is polyether foaming (sponge), and polyester foaming two kinds.

China now routinely uses polyether foam (sponge), the use of pure raw material production without filler, which has the highest density of about 30 kg/cubic meter, The advantage is low density, good water absorption, and adding wear-resistant coating can complete the pigging function. Polyether foam (sponge) high-density general packing (calcium powder) to adjust the density, adding filler products fragile, generally not suitable for pipeline application.

Now the conventional use of polyester foam abroad, density is generally more than 250 kg/cubic meter, The advantage is good wear resistance, not broken. The disadvantage is that the water absorption performance is not as good as the low-density sponge. Purpose: Suitable for pipeline cleaning applications, especially for long-distance and submarine pipeline applications.

The sponge is usually made of high-density foam made of polyurethane vinegar. It is also called “Pig”. The surface of this kind of pig is coated with high strength. Good wear resistance flexible good, with excellent solubility of polyurethane vinegar bomb 1 LAN body in this layer of elastic surface sometimes accompanied by a wire brush or basil needle attached to the wire brush called wire brush pig emperor has a special shape of the needle called nail pig These two kinds of day suitable for removing more firmly attached to the wall of the dirt.

If a low-density polyurethane vinegar foaming system is used to form soft pig, it has the characteristics of good shrinkage, which is suitable for the early clearing cleaning treatment to check whether there is a foreign body in the pipeline and can use its good hygroscopic characteristics. It is specially used to remove moisture and oil from new pipes. It can also be used to remove sludge and soft dirt from pipes.

Pig foam prevention and disposal

The biggest risk with pigs is clogging. The foreign method to prevent pigging is to develop a self-plugging type of pig. During operation, the quantity and structural strength of the wax deposits in front of the pig can be identified. If the value exceeds the set critical strength, the shear device will start induction to destroy the wax crystal structure and prevent the pigging caused by the accumulation of wax deposits. The domestic pipeline practice shows that the main reasons for pig jam are pipeline deformation, elbow radius less than the minimum allowed radius of pig, too much water and dirt in the pipeline, unreasonable base design, and so on.

Matters needing attention

1. Choose the right foam pig: There are many types and specifications of foam pigs, and the right pig should be selected according to the actual needs. For example, different types of pig are required for different pipe diameters, lengths, bending degrees, etc.

2. Safe use: Pay attention to safety when using the foam pig and wear proper protective equipment such as gloves and goggles to avoid injury.

3. Correct operation: Before using the foam pig, it is necessary to understand the cleaning condition and cleaning method of the pipe, and select the appropriate cleaning method and cleaning agent according to the characteristics and structure of the pipe. When cleaning agents, follow the proper steps according to the instructions and pipe layout. Do not abuse or overuse cleaning agents.

4. Storage and maintenance: After use, the foam pig should be cleaned promptly and stored in a dry, ventilated place. Foam pigs that have been stored or unused for a long time should be checked and cleaned regularly to keep them functioning well.

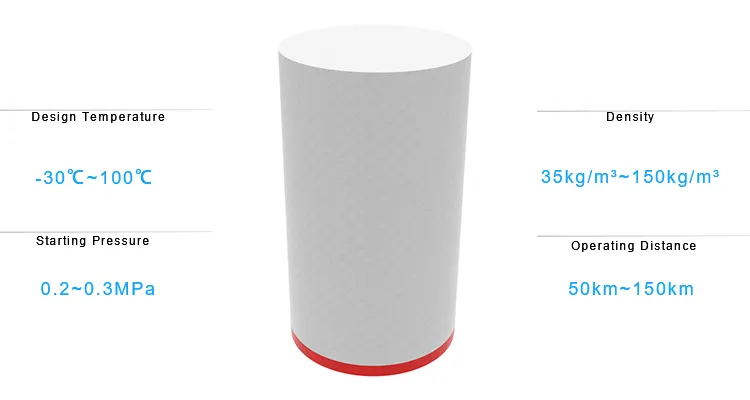

bare foam pig

Reviews

There are no reviews yet.