Description

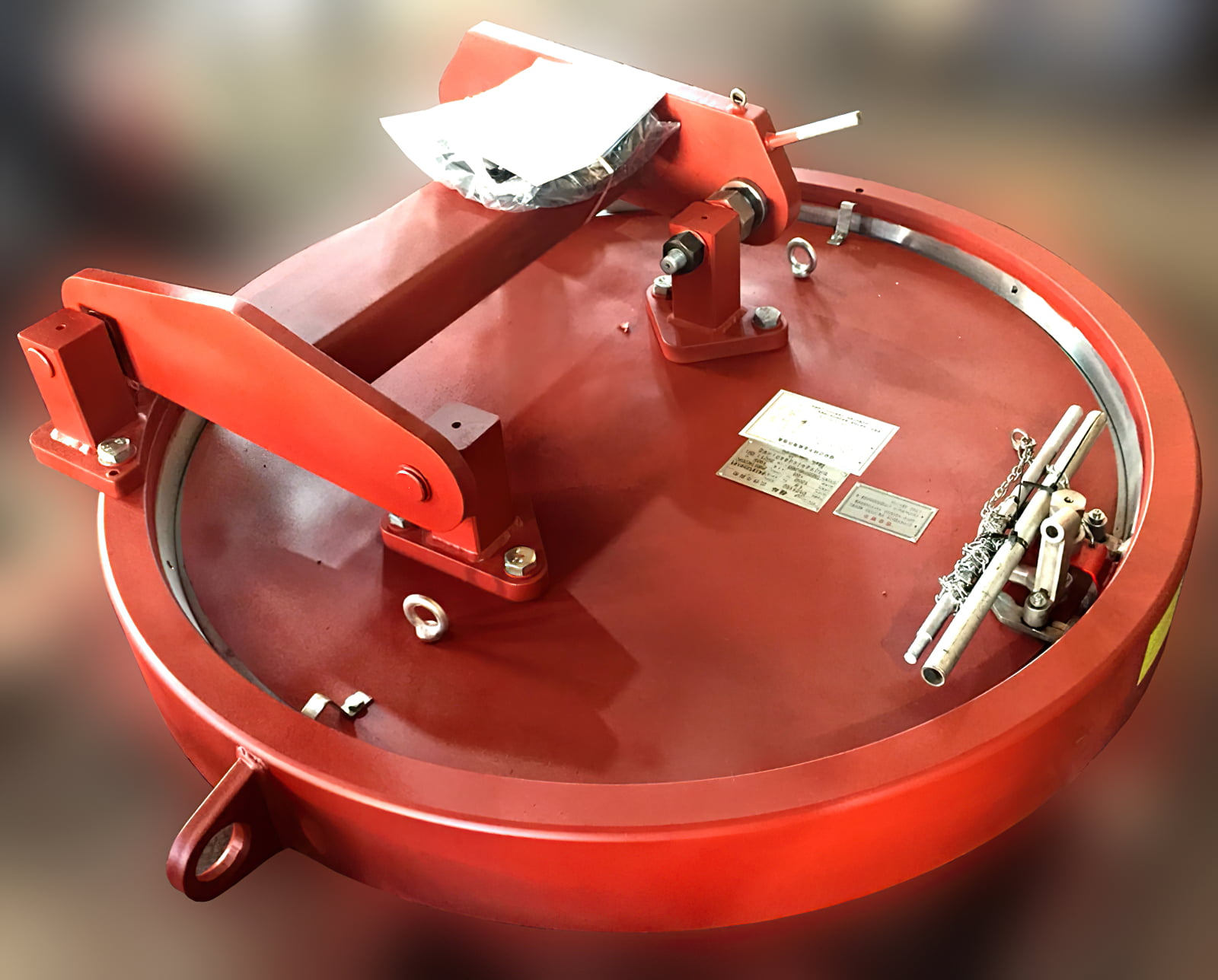

Quick opening closure a mechanical device is used in the circular opening of a pressure pipe or vessel for rapid opening or closing.

Quick opening closure operating procedures

Open the ball cylinder vent valve, so there is no pressure inside the cylinder, And cut off all air sources;

Slowly loosen the safety lock valve. When there is material overflow from the valve interface gap, stop twisting the valve. When there is no more material overflow in the equipment, completely unscrew the safety lock valve to reduce the remaining pressure in the chamber to atmospheric pressure;

Remove the safety card;

Turn the switch lead screw in the direction indicated at the switch lead screw until the inner edge of the clamp is completely separated from the outer edge of the blind plate cover;

Hold the blind plate cover handle and open the blind plate cover to one side.

Shut down

Thoroughly remove dirt in the adagio sealing surface, sealing groove, type 0 sealing ring, and clamp, apply anti-rust grease, and then install type 0 sealing ring;

Pull the handle on the blind plate cover and close the adagio cover to make the blind plate cover completely coincide with the outer edge of the blind plate seat. If there is a small amount of wrong edge between the blind plate cover and the blind plate seat, you can make the blind plate seat completely coincide with the outer edge of the blind plate cover by adjusting the adjusting nut and the adjusting bolt on the adjusting nut;

Turn the opening and closing lead screw in the direction marked at the support to lock the clamp;

Install the safety clipboard so that the safety clipboard is completely fastened to the safety positioning pin;

Check whether the O ring on the safety lock valve is in good condition

Install the safety lock valve and tighten it so that the blind plate is completely closed.

Close the vent valve, open the injection valve, and check the leakage;

If there is no leakage, close the air injection valve, and open the air valve after pressure relief is closed;

Clean the site and paint anticorrosive paint (if the anticorrosive paint falls off).

Matters needing attention

Before opening the quick opening closure, it is necessary to open the ball cylinder vent valve. Only when there is no pressure in the cylinder, can it be operated (this equipment is forbidden to open with pressure).

The operator shall stand on one side of the opening and closing mechanism, and no personnel or equipment shall stand or place directly against the blind plate.

Pressure relief devices shall not be used. The safety lock valve must be tightened after closing the blind plate.

Daily maintenance

The person operating the blind plate must understand its structure and operating procedures;

Ensure that the blind plate is completely closed before the equipment is pressurized;

When the equipment is running, it is forbidden to knock or collide with the main pressure components of the adagio;

The opening and closing screw, hinge shaft, pin shaft, and other rotating devices of the blind plate must be regularly coated with lubricating oil to keep lubricated. The above parts are filled with lubricating oil (fat) once every 3 months; The hinged shaft and the lead screw are lubricated with glycerin, and the pin shaft is lubricated with oil from the oil-filling hole;

Keep the paint on the outer surface of the blind plate complete and smooth;

Regular inspection of the main bearing parts of the blind plate cover, blind plate seat, clamp, hinged shaft, lead screw, and other parts, if there is deformation, serious corrosion or crack, to find the cause in time, and properly handle;

Before the blind plate is closed each time, the sealing groove, sealing surface, and type 0 sealing ring should be cleaned, inspected, and lubricated to prevent failure to seal during use.

Quick opening closure failure cause and troubleshooting method

Quick opening closure seal ring leakage

There is dirt on the surface of the sealing groove, sealing surface, and 0-type sealing ring

Clean it up and install the seal ring.

Aging of the sealing ring

Replace the seal ring

Leakage at safety interlocking device

There is dirt on the surface of the sealing groove, sealing surface, and 0-type sealing ring

Clean it up and install the seal ring.

Aging of sealing ring.

Replace the seal ring.

Leakage of other parts

Find out the cause of leakage in time and inform the manufacturer

The supplier provides the treatment plan

Blind plate cover and blind plate seat misalignment

The rotating mechanism component is loose or out of position

Adjusting nut on the rotary hinged shaft in dislocation adjustment up and down; Adjust the positioning screws on the shaft sleeve for left and right dislocation.

Other faults

Contact the supplier promptly

Maintenance

Before pressurizing the pressure vessel with a blind plate, the blind plate must be installed before it can be pressurized and put into use. After being put into use, it is not allowed to knock and collide with the main pressure parts. The surface of the blind plate must always keep the paint complete and smooth. Regular inspection of the main bearing parts of the blind plate (such as the blind plate cover and the simplified surface). If serious corrosion or cracks are found, the cause should be found in time and properly handled. After each use, the sealing rubber ring and sealing groove should be cleaned, inspected, and lubricated, in case they cannot be sealed during use.

Risk tips and reduction measures

Risk warning: When opening the blind plate, the residual pressure in the ball cartridge will cause harm to the human body;

Reduction measures: Make the vent system in a fully open state;

Personnel stands on the outside of the blind plate to operate.

Risk warning: damage to the human body when operating the blind plate;

Reduction measures: Set up a safety guardian on-site, and prohibit people from standing in front of the blind board.

quick opening closure

Reviews

There are no reviews yet.