Description

Application scope

Product Features

The lock ring type has an integrated retractable lock ring structure. Compared with various forms of quick opening closure in the past, it greatly reduces the opening and closing time, and only one person can easily complete it within one minute with less than 200N force; Its unique self-tightening lip sealing structure makes the sealing more safe and reliable; The safety locking system has the safety self-locking function. Its function is as follows: before the pressure boost of the equipment, the quick opening closure and its locking mechanism can be fully locked on the predetermined operating position. If the equipment does not reach the predetermined locking position, the pressure boost of the equipment cannot be achieved. After the equipment pressure relief and before the blind plate cover is opened, the internal pressure of the container can be completely discharged to realize secondary pressure relief and avoid potential safety risks caused by misoperation.

Structure type and composition

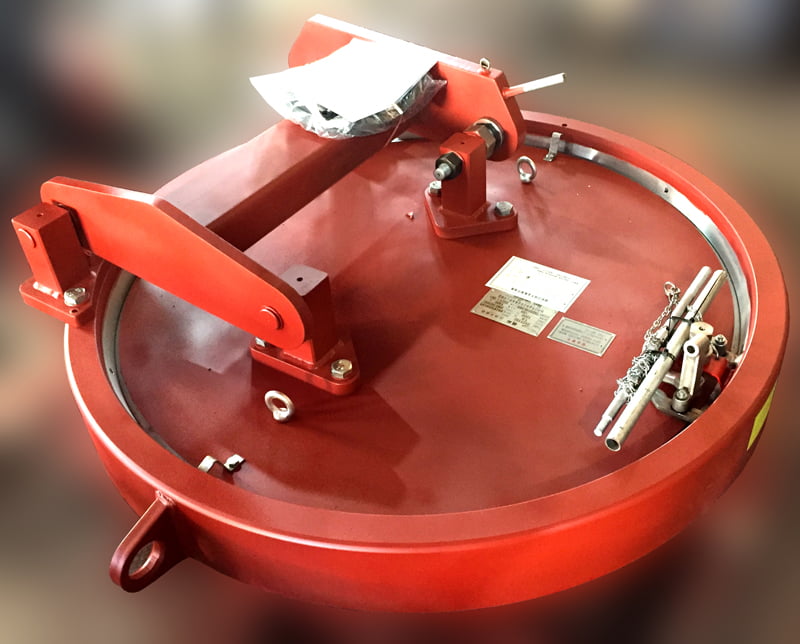

Lock ring type quick opening closure is composed of a blind plate cover, cylinder flange, retractable integral lock ring, self-tightening lip seal ring, door opening mechanism, safety locking device, etc.

Installation and adjustment

Welding of the cylinder flange

Clean the connection between the simplified flange and the cylinder, align the inner hole, find a good position, and weld according to the hinge position of the door opening mechanism.

Generally, the simplified flange is designed according to the user’s simplified material. Its welding performance is the same or similar to that of the cylinder material. Without special instructions, it can be welded with the welding material of the cylinder body.

Heat treatment

After welding the simplified flange with the simplified flange, according to the requirements of GB150-1998 for heat treatment, it is appropriate to use local heat treatment, heat treatment should pay attention to protecting the sealing surface, avoiding bumps, scratches, etc.

Inspection and acceptance

After thermal treatment of the cylinder flange and the cylinder body, the weld must be 100% X-ray detection, grade 11 qualified.

Adjust

Clean the sealing surface of the simplified flange and blind plate cover and close the blind plate. Adjust the blind plate cover with the adjusting nut on the door hinge seat to make the clearance between it and the cylinder body evenly and ensure that the lock ring is retractable freely. Each connection, connection thread, rotation part, lock ring end face, and sealing surface should be coated with anti-rust grease.

Open quick opening closure

Opening sequence: Drain the pressure inside the equipment, slowly rotate the alarm screw, confirm the internal pressure is zero, and screw out the alarm screw; Screw the alarm screw into the threaded hole of the insert as a handle to remove the insert (safety plate); Turn the booster rod of the locking mechanism counterclockwise to close the locking ring in place and open the blind plate cover.

Close the blind plate quickly

Closing sequence: After the two ends of the lock ring are coated with anti-rust lubricant, pull the after rod counterclockwise to close it, thoroughly clean the sealing groove of the sealing surface of the cylinder flange and the blind plate cover, check whether the sealing ring is intact, and apply anti-rust grease; Push the blind plate cover into the blind plate slowly and in parallel. After it is in place, turn the afternoon of the locking mechanism clockwise to open the locking ring; Put the insert (safety plate), screw the alarm screw into the blind plate cover through the insert and tighten it (pay attention to the sealing rubber ring do not fall off).

Safe operation and maintenance

The operator must read this manual carefully to understand the structure and use of the lock ring blind plate;

The sealing ring shall be taken out when the equipment is welding with the cylinder to avoid the sealing ring being damaged due to excessive heat during welding

Before opening the blind plate, it is necessary to screw the alarm screw first and pay close attention to whether there is gas leakage in the process of spinning out. If there is, the operation should be stopped immediately;

When the blind plate cover is closed, after the insert (safety plate) is placed in place, the alarm screw should be screwed through the insert again. Please check before screwing. Type B rubber seal ring is well placed. It is strictly prohibited to screw the alarm screw directly without inserting the insert;

The whole product should be hoisted by the hoist on the cylinder body, and it is strictly prohibited to use the hoist ring screw on the blind plate cover;

During the working process, it is strictly prohibited to hit and impact the pressure parts:

After use, each connection thread, rotation part, lock ring surface, and sealing surface should be coated with anti-rust grease;

If the equipment is not used for a long time, the connection thread, rotation part, lock ring surface, and sealing surface, at least once a year cleaning, and coated with anti-rust grease;

If the quick opening closure is installed outdoors, protective measures should be added;

The main pressure parts of the quick opening closure(blind plate cover, simplified flange, lock ring, etc.) should be checked regularly. If serious rust and crack are found, the cause should be found in time and professionals should be asked to deal with it.

Accessories

Safety device sealing ring two lip sealing ring assembly a set

quick opening closure

Reviews

There are no reviews yet.