Description

Structure

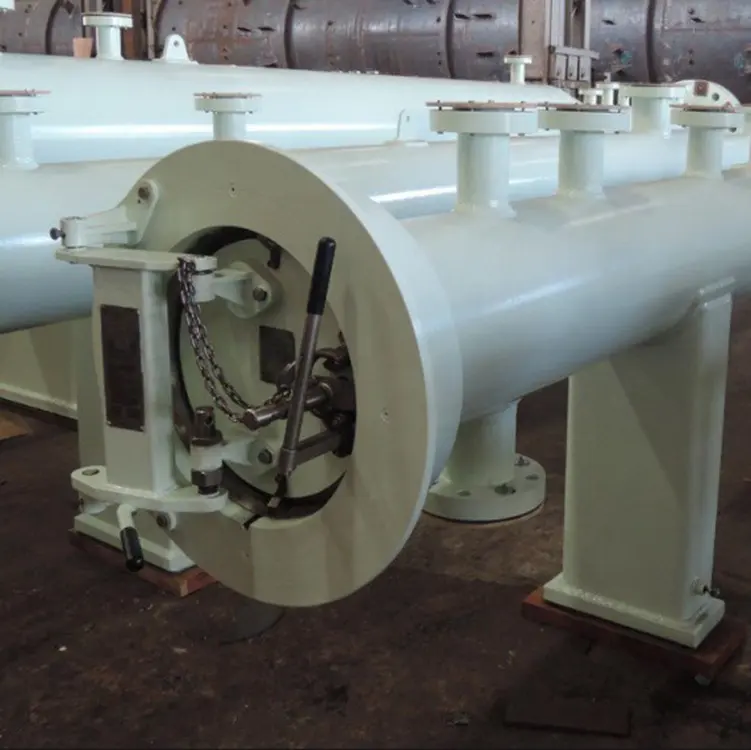

Quick opening closure can be divided into several typical structures, such as tooth insert type, clamp type, lock ring type, and buckle type

Quick-opening blind plate maintenance

Open the quick opening closure

Maintenance of quick opening closure

1. Open the blind plate, remove the sealing ring from the door, and check whether there is mechanical damage on the surface of the sealing ring, if there is, replace it; If not, clean it with a clean cloth dipped in a degreaser, and then dry with a clean cloth temporarily put in a clean place for safekeeping;

2. Check whether there is rust and dirt in the sealing groove. If there is, clean it with high-quality fine sandpaper and dry it with a clean cotton cloth;

3. Check the inside of the neck of the blind plate and the part that the door touches when it is closed, including the slot of the door. If dirt or rust is found (especially the bottom), clean it with sandpaper and dry it with a clean cotton cloth;

4. After the above places are clean, apply silicone oil or another similar grease (lithium grease), The place that needs to be greased includes: the groove (located in the lower part of the sealing ring after coating, install the seal, the outer side of the seal should also be greased); The contact surface between the door and the inside of the neck after closing; The contact surface between the locking belt and the door (the contact part between the sealing ring and the cylinder) :

5. Closing the blind plate After the blind plate is closed, the receiving cylinder or filter separator should be gradually charged, which can be divided into three steps: low pressure (0.1-0.2MPa), medium pressure (1/2 of the pressure of the main line under the current operating condition) and high pressure (the pressure of the main line under the current operating condition). The interval between each step should be at least 20 minutes and the combustible gas detector should be used for uninterrupted detection.

6. Quick opening closure front and inside can not stand people

7. The person who uses the blind plate must understand the structure and operation procedures of the blind plate;

8. Open the empty valve before opening the blind plate cover. Open the blind plate only when the pressure in the container is reduced to zero.

9. Before pressurizing the pressure vessel with a blind plate, the blind plate must be installed before it can be pressurized and put into use;

Common faults of quick opening closure and treatment methods

Blind plate leakage

If the blind plate is still leaking after normal maintenance

Open the blind plate, and check that the blind door is in the middle of the neck, otherwise, adjust the blind door centering.

Mark the sealing ring and sealing groove at 3 o ‘clock, 6 o ‘clock, 9 o ‘clock, and 12 o ‘oclock respectively with a grease soft pen, and rotate the sealing ring 90 degrees clockwise.

Carry out normal maintenance and maintenance procedures

Boost the pressure to check whether the blind plate has external leakage

Leakage at safety interlocking device, There is dirt on the surface of the sealing groove, There is dirt on the surface of the sealing groove, sealing surface, and type 0 sealing ring; The sealing ring is aging. Clean it up and install the seal ring。

Blind plate cover and blind plate seat misalignment, The parts of the slewing mechanism are loose or out of position, Dislocation up and down: adjust the adjusting nut on the rotary hinged shaft; Left and right dislocation: Adjust the positioning screws on the shaft sleeve

Adjustment of the blind door center

Remove the lock strap from the door;

Remove the seal from the door;

Close the door, ensure that it is vertically installed on the neck, and measure the size of the surrounding gap with a feeler.

Adjustment of lock straps

Extend the lock band to the “locked” position, and then use the tightening member to clamp the release screw;

Adjust the eccentric stop so that it can provide a rotating installation for the lock strap handle;

Protect the eccentric stop device by tightening the hex countersunk nut

Check the operation of the locking belt by extending and shrinking the locking belt;

Replacing the sealing belt

Remove the seal from the groove to ensure that there is no damage to the sealing groove;

Remove the old sealing belt, clean the sealing groove, and coat with a thin layer of silicone grease;

Press the sealing tape into the groove at the top, ensuring that the seal is in the center of the groove, and then press the sealing tape into the groove symmetrically.

Matters needing attention

1. Check that the indicators on the container are normal;

2. Check the container and the quick opening closure connection parts should not leak;

3. Necessary explosion-proof tools, fire extinguishers, fire MATS, and other facilities are ready;

4. The operation of opening and closing the blind plate is carried out by one person and monitored by other personnel;

quick opening closure

Reviews

There are no reviews yet.