Description

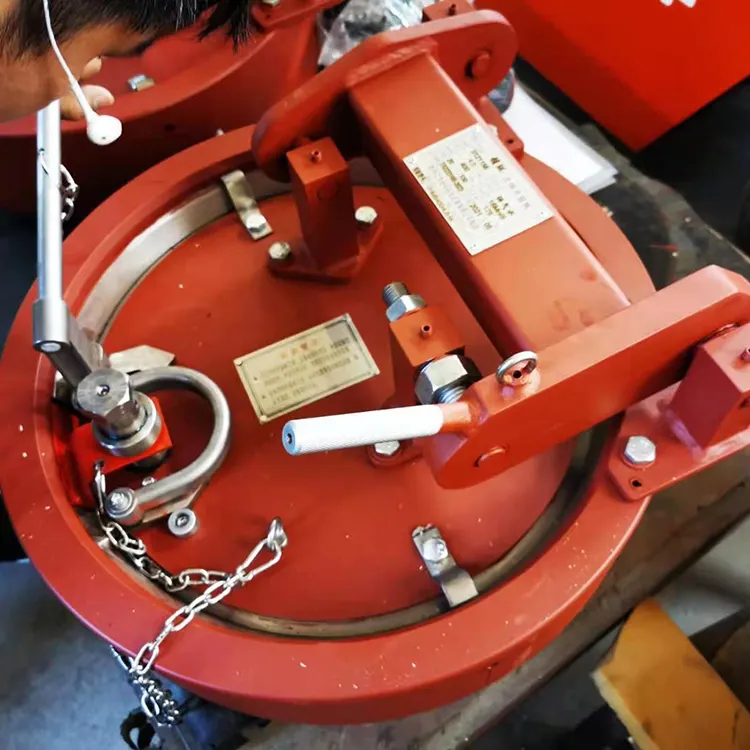

The quick opening closure is a mechanical device used to quickly open or close the circular opening of the pressure pipeline or pressure vessel. It is a key part of the oil and gas pipeline equipment and is widely used at the end of the filter separator, filter, and receiving cylinder. When the equipment is working, it is under static pressure. Its locking mechanism needs to be opened and closed by movement. Pressure vessels with quick opening closures as end caps belong to quick-opening type pressure vessels, which are widely used in petrochemicals.

Structure

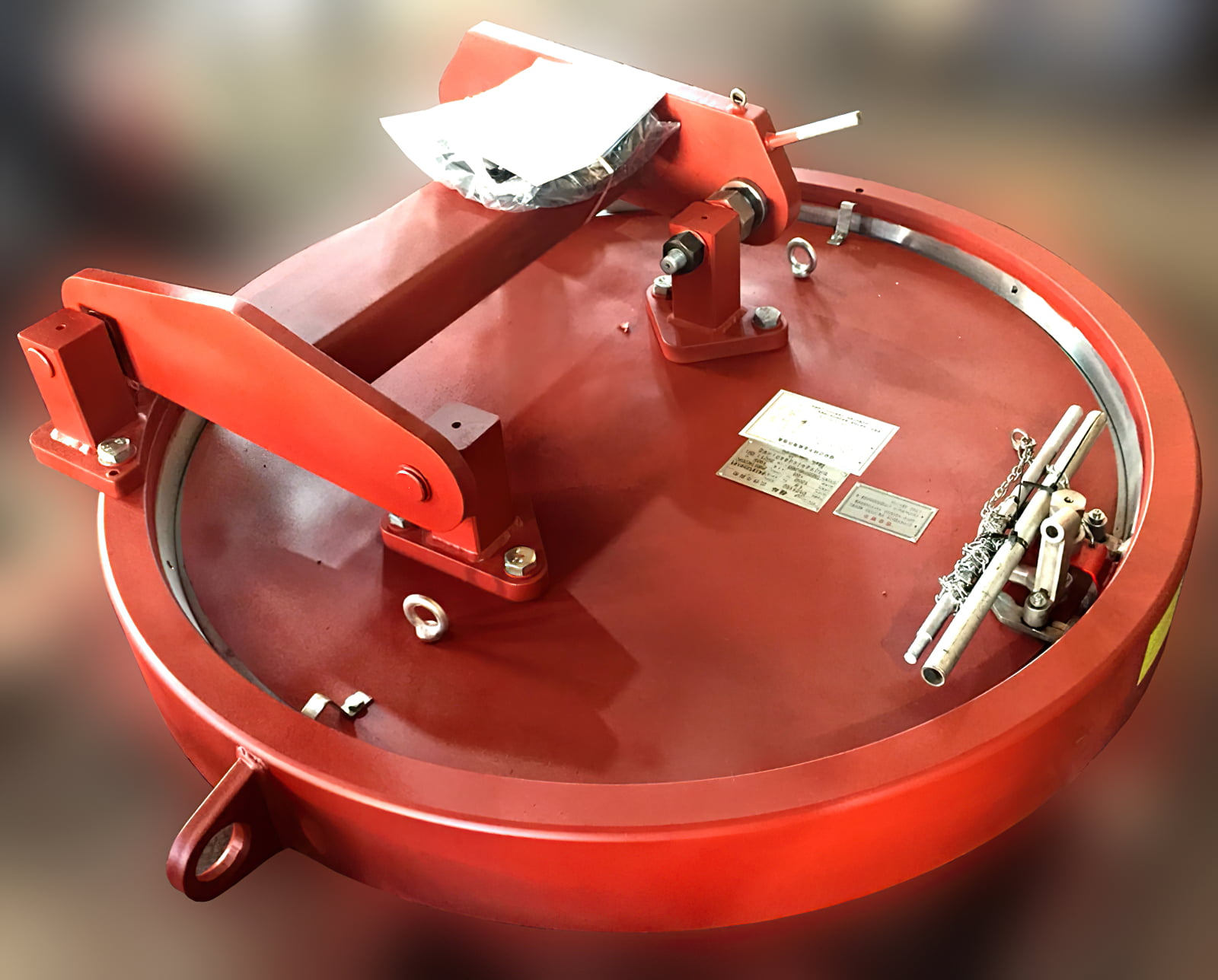

The safety self-locking quick opening closure is divided into horizontal and vertical installation forms. The horizontal safety self-locking quick opening closure is mainly composed of a head cover, end flange, sealing ring, locking mechanism, safety interlock and alarm mechanism, and opening and closing mechanism. The vertical safety self-locking quick opening closure is mainly composed of a head cover, end flange, sealing ring, locking mechanism, safety interlock, alarm mechanism, lifting mechanism, and rotating mechanism; The locking mechanism is divided into two sections by a conical locking ring, and the small section is connected with the release bolt through a connecting plate as a locking block; According to user needs, vertical and horizontal can be equipped with remote alarm device and mechanical key safety lock; General horizontal and small and medium-sized vertical safety self-locking blind plate adopts manual operation, large vertical blind plate adopts electric operation.

1. Dual-phase stainless steel clasp makes 360 degrees uniform pressure, and the conical thrust ring is tilted and stuck between the door and the flange so that the lock ring is not subject to shear force;

2. The clasp type is an external lock, the locking state is clear to the operator, fully in line with ASME standards, providing a 100% safety guarantee;

3. Snap ring lock operation is simple, just retract or expand the locking belt and zero faults:

4. Because the lock ring is external, the GD door should be light in weight.

Horizontal and vertical

According to the needs of practical applications, we provide two kinds of horizontal and vertical. The horizontal opening mode is left or right rotation through the door shaft, and the vertical opening is lifted up through the davit.

Performance index

(1) Advanced design: Based on the lock ring type, the use of an internal extension head cover, and compact structure, the design considers the influence of fatigue load, the use of finite element analysis and design method, integrating science, economy, and safety.

(2) Structural self-locking: The locking structure adopts the self-locking principle, and the duplex stainless steel conical self-locking ring converts the shear force of the general locking ring structure into compressive stress, improving the state of the force.

(3) Reliable sealing: The sealing ring is made of stainless steel and rubber, and the sealing mating surface is made of a flat push structure, reliable performance, and easy maintenance.

(4) Multiple interlocking and double alarms: The pressure relief bolt and the lock block are connected as one through the connecting plate. In the case of residual pressure, when the release bolt is not removed, the lock block connected as one can not be removed, the large section of the lock ring cannot be retracted, and the head cover cannot be opened; Optional remote transmission alarm device, control room operators can easily understand the opening state of the blind plate; The lifting and rotating mechanism of the large vertical blind plate are automatically interlocked, the operation of the first step is not in place, and the next step cannot be started; Optional mechanical key safety lock to prevent misoperation.

(5) Open efficient and convenient: One person does not need any special tools within 1min, only needs to rotate the handle 180°, You can easily open the lock ring, horizontal blind plate 1 person to open the blind door, vertical blind plate no matter how big the size, 1 person easily complete the blind plate opening, rotation and lifting work within 5min, large vertical blind door lifting and rotation realized automation.

The quick opening closure is a mechanical device used for the circular opening of the pressure pipeline or pressure vessel and can achieve rapid opening or closing. It is generally composed of the cylinder flange, head cover, hook ring or clamp, sealing ring, safety interlock mechanism, opening and closing mechanism, rotating arm, and short section (when necessary).

Seal

Rubber and stainless steel · springs are manufactured as one

The reason we designed it as one is that the two separate components had a history of springs being squeezed out of the sealing slot under pressure. Designed for rest, the seal is both elastic and rigid, completely avoiding the occurrence of leakage accidents.

Flange

Due to the pressure on the flange near the door, the designed flange is very thick and never deformed after heat treatment;

Pressure alarm

The pressure alarm device and the small segment of the lock ring are integrated

The purpose of the design as a whole is that in the case of residual pressure, the pressure alarm device, that is, the pressure relief bolt assembly, is not removed so that the small section of the lock ring connected as a whole can not be removed, the large lock ring can not be retracted, and the door can not be opened. It’s an interlock for safety.

quick opening closure

Reviews

There are no reviews yet.